Aftermarket Options That Help Fuse Box Replacements Match Original Equipment Standards

News 2025-12-22

When an automotive or industrial fuse box reaches the end of its service life, decision makers often look beyond the OEM catalog to control cost and lead time. Aftermarket fuse box assemblies can satisfy the same electrical, mechanical, and safety criteria as original units when they are engineered and qualified to equivalent standards. Selection focuses on material quality, circuit rating accuracy, environmental protection, and compatibility with existing harnesses and mounting points.

Key Technical Requirements Matching OE Performance

Aftermarket fuse boxes that truly match OE standards typically align with specifications such as ISO, IEC, and SAE regulations on current handling, dielectric strength, and thermal stability. High-grade thermoplastic housings maintain dimensional integrity near hot engines or in sealed control cabinets. Copper or copper-alloy busbars and terminals must offer low contact resistance and robust plating to minimize temperature rise under continuous load. Accurate labeling, standardized blade or mini-blade fuse interfaces, and clear circuit mapping enable drop-in replacement without rewiring or redesign.

Application Scenarios In Automotive And Industrial Systems

Automotive applications include passenger vehicles, commercial trucks, buses, and off-highway equipment where the fuse box concentrates power distribution for lighting, HVAC, drivetrain, and safety systems. In these environments, aftermarket units must endure vibration, humidity, road salt, and engine compartment temperatures while preserving IP-rated sealing. Industrial uses span machine tools, conveyor lines, process control panels, and renewable energy inverters, where panel-mounted or DIN-rail fuse boxes manage multiple branch circuits. Correct short-circuit ratings and coordination with upstream breakers are vital to prevent nuisance downtime and protect semiconductors, sensors, and control electronics.

Performance Advantages Of High-Grade Aftermarket Designs

Well-engineered aftermarket fuse boxes often surpass legacy OE units in thermal management, layout flexibility, and serviceability. Optimized busbar geometry and venting reduce hot spots, supporting higher continuous currents or denser circuit groupings without derating. Modular cavities allow technicians to reconfigure circuits, add relays, or integrate monitoring accessories while preserving footprint. Enhanced terminal retention features and secure cover latching limit micro-arcing and moisture ingress, extending fuse life. These performance advantages translate into lower maintenance frequency, fewer field failures, and improved safety margins throughout the electrical system lifecycle.

Selection, Certification, And Integration Considerations

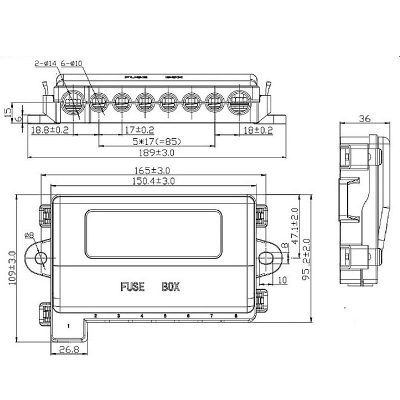

To ensure OE-level quality, buyers should prioritize manufacturers that test their fuse boxes to UL, CSA, ECE, or comparable regional approvals, and provide documented current-carrying capacity, insulation resistance, and temperature rise data. Dimensional drawings and 3D models support precise fitment in crowded engine bays or compact control cabinets, while cross-reference tools map OE part numbers to compatible aftermarket assemblies. When integrating into existing wire looms, matching terminal types, cavity counts, mounting tabs, and cover-clearance requirements prevents strain on connectors and avoids unintended derating. Collaboration between design engineers, procurement teams, and installation technicians helps ensure that the selected aftermarket fuse box performs on par with the original unit from initial commissioning through long-term operation.

Common Questions About OE-Matching Aftermarket Fuse Boxes

1, How can I verify that an aftermarket fuse box matches OE electrical ratings?

Check the datasheet for continuous current ratings, peak short-circuit capability, and applicable standards such as UL or ISO. These values should equal or exceed those listed for the original component, including ambient temperature assumptions.

2, Are aftermarket fuse boxes suitable for harsh automotive underhood environments?

Yes, when the enclosure uses heat-resistant plastics, sealed covers, and corrosion-resistant terminals validated through vibration, thermal cycling, and salt spray tests that reflect underhood conditions.

3, What integration checks are important before replacing an OE fuse box?

Confirm mounting dimensions, connector styles, fuse formats, and branch circuit counts. Ensure harness strain relief, cover clearance, and IP rating are maintained so the new assembly does not compromise system protection.