Automotive Battery Box Solutions for Fleet Vehicles with Consistent Performance and Safety

News 2025-11-17

The rapid growth of commercial fleets in logistics, ride‑hailing, and municipal services has pushed demand for automotive battery boxes that maintain stable performance in demanding duty cycles. Fleet operators require energy systems that support high daily mileage, frequent fast charging, and exposure to harsh environments while keeping maintenance costs predictable. A well‑engineered battery box becomes the structural and thermal foundation that protects cells, stabilizes output, and supports the data collection needed for modern fleet management.

Key functions and design considerations

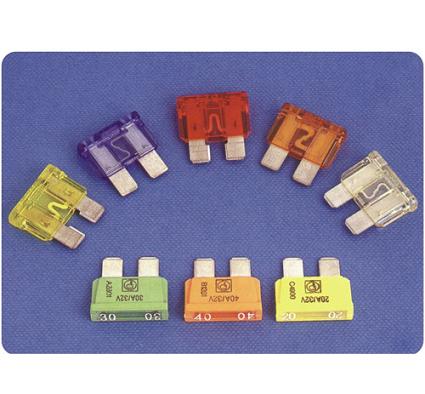

A fleet‑grade automotive battery box integrates mechanical protection, electrical interfaces, thermal regulation, and sensing hardware in a single enclosure. The housing must resist vibration, road debris, moisture ingress, and corrosion over hundreds of thousands of kilometers. Designers select aluminum alloys or high‑strength composites with optimized stiffness‑to‑weight ratios to protect the battery pack without adding unnecessary mass. Internal layouts create controlled compression on cell modules, maintain creepage and clearance distances on busbars, and support high‑current connectors, fuses, and contactors. Integrated wiring harnesses, current sensors, and high‑voltage interlocks connect to the battery management system, providing accurate data for state‑of‑charge, state‑of‑health, and predictive maintenance analytics.

Performance consistency for high‑utilization fleets

Commercial fleet vehicles operate with far higher utilization than private cars, often performing multiple shifts per day. To keep energy delivery consistent, battery boxes employ carefully designed thermal paths, including liquid cooling plates, heat spreaders, and insulation layers that limit temperature gradients between cells. This temperature stability reduces capacity fade, lowers internal resistance growth, and improves charge acceptance, which translates directly into consistent driving range and predictable charging times. High cycle‑life chemistries combined with robust enclosures allow fleet operators to maintain similar performance profiles across the vehicle lifetime, simplifying route planning and reducing downtime caused by unexpected range reduction.

Application scenarios and installation options

Battery box architectures differ by vehicle segment and mounting location. In last‑mile delivery vans, under‑floor battery boxes free cargo volume while lowering the center of gravity to improve handling on urban routes. For electric buses and heavy‑duty trucks, frame‑mounted side packs with reinforced crash structures provide high capacity and easy access for service technicians. Ride‑hailing and car‑sharing fleets often favor modular battery box designs that support standardized pack sizes across multiple vehicle platforms. This modularity streamlines inventory management, enables partial pack replacement, and allows operators to deploy the same battery family in city cars, compact vans, and light trucks, improving purchasing leverage and simplifying technical training.

Safety, durability, and electronic protection

Safety is central to battery box design for fleet vehicles that operate in crowded depots and public streets. Multi‑layer protection includes rigid enclosures, sealed gaskets, pressure relief paths, and flame‑retardant materials that slow thermal propagation in case of cell failure. Sensing electronics detect overcurrent, overvoltage, leakage, and abnormal temperature rise, triggering fast isolation through high‑voltage contactors and fuses. IP‑rated seals and venting solutions prevent water ingress while managing condensation and pressure changes across wide temperature ranges. These features support compliance with automotive safety standards and give fleet owners confidence that vehicles can endure daily fast charging, intensive acceleration, and long‑term storage without compromising occupants or cargo.

Impact on fleet economics and sustainability

Stable battery box performance has a direct influence on total cost of ownership for fleet operators. Consistent capacity and internal resistance reduce the need for premature pack replacement and allow operators to fully utilize scheduled lifetimes in leasing or pay‑per‑kilometer models. Accurate monitoring of cell conditions within the box supports data‑driven maintenance planning, allowing packs to be rotated, reallocated, or repurposed into second‑life stationary storage with minimal disruption. The combination of durable housings, recyclable materials, and standardized interfaces helps organizations meet sustainability targets while maintaining predictable energy costs per kilometer.

1. How does a battery box support telematics integration?

The enclosure hosts current sensors, voltage taps, and communication interfaces that stream real‑time battery data to fleet management platforms, enabling remote diagnostics, usage analytics, and route optimization.

2. Why is thermal design so important for fleet applications?

Stable cell temperature improves charge efficiency, slows capacity degradation, and keeps driving range predictable, which is critical for vehicles that operate almost continuously throughout the day.

3. Can one battery box platform serve multiple vehicle models?

Yes, modular designs with standardized mounting points, connector layouts, and cooling interfaces allow the same battery box family to be adapted across different vehicle segments, reducing engineering and inventory costs for fleet operators.