Ignition Coil Fuse Design Enhances Engine Efficiency and Electrical Protection

News 2025-11-17

An ignition coil fuse protects ignition coils from electrical overloads, preventing coil burnout and safeguarding the engine control system. In modern gasoline engines, the ignition coil converts low battery voltage into the high voltage required to fire spark plugs. This high-energy operation exposes coils to current surges, short circuits, and wiring faults. By placing a correctly rated fuse in the ignition circuit, manufacturers improve system safety, maintain stable ignition performance, and reduce maintenance costs across passenger cars, light trucks, motorcycles, and small industrial engines.

Function and Working Principle of the Ignition Coil Fuse

The ignition coil fuse is a sacrificial component designed to open the circuit when current exceeds a defined threshold. Under normal conditions, current flows from the battery through the fuse to the ignition coils and associated control electronics. If a coil internally shorts, wiring insulation fails, or a connector becomes damaged, current rises rapidly. The fuse element heats up and melts, breaking the circuit before the excessive current can damage coils, the engine control unit (ECU), or upstream wiring. Correct fuse selection, based on coil resistance, maximum dwell current, and system voltage, ensures fast interruption while avoiding nuisance blowing during normal engine start or high-load operation.

Key Performance Characteristics and Advantages

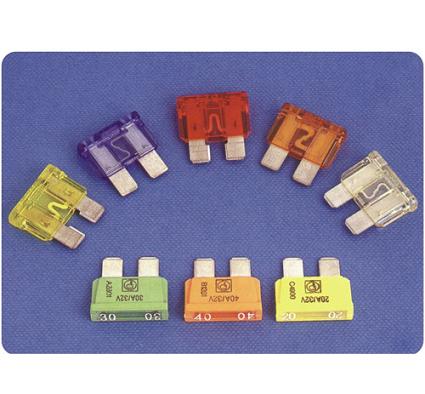

Performance of an ignition coil fuse is determined by rated current, voltage rating, time-current curve, and interrupting capacity. Automotive applications typically require fast-acting blade or mini-blade fuses that react quickly to short circuits yet tolerate brief inrush currents during cranking. A properly matched fuse minimizes coil overheating, reduces the risk of ECU failure, and improves overall ignition stability. High interrupt ratings allow safe clearing of severe faults without arc damage. Using quality fuses also simplifies fault localization: when a coil circuit fails, the blown fuse provides a clear diagnostic indicator, shortening repair time and reducing downtime in fleet and industrial environments.

Application Scenarios in Automotive and Industrial Systems

Ignition coil fuses are widely used in passenger vehicles, commercial fleets, motorcycles, marine engines, and generator sets. In multi-coil systems such as coil-on-plug architectures, individual or grouped fuses protect separate coil banks, supporting modular maintenance and enhanced fault isolation. In hybrid and start-stop vehicles, fuses must withstand frequent engine restarts and elevated under-hood temperatures, making thermal stability and vibration resistance crucial selection criteria. Small industrial engines in pumps, lawn equipment, and construction machinery rely on ignition fuses to prevent unexpected shutdowns caused by wiring damage or moisture ingress, maintaining stable operation in harsh environments.

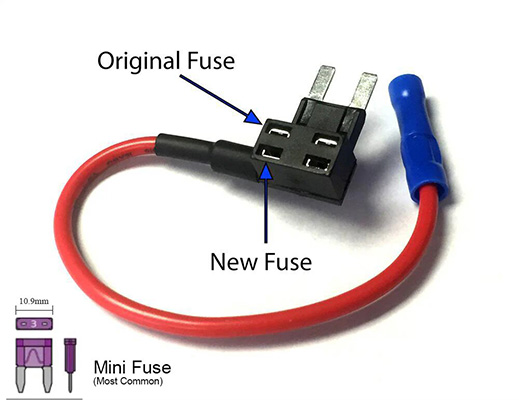

Selection, Installation, and Maintenance Considerations

Correct sizing of the ignition coil fuse begins with analyzing coil current at cold and hot conditions, ECU dwell control strategy, and ambient temperature. Engineers typically choose a fuse rated slightly above maximum continuous coil current yet low enough to respond quickly to faults. Installation in sealed, automotive-grade fuse boxes protects the fuse from dust, oil, and splash water, while clear labeling supports fast service. Regular inspection during scheduled maintenance helps detect heat discoloration, corrosion, or loosened terminals that can lead to voltage drops and misfires. Using original-spec or certified replacement fuses prevents under-rated substitutions that may blow prematurely or over-rated parts that fail to protect the ignition system.

1. What symptoms indicate a blown ignition coil fuse?

Engine cranking without starting, multiple cylinder misfires, sudden loss of spark, or an inactive ignition coil bank often indicate a blown fuse. Checking the fuse box is a quick first diagnostic step.

2. Can a higher-rated fuse be used to prevent repeated failures?

Using a higher-rated fuse is not recommended, as it may allow excessive current that damages coils, wiring, or the ECU. Repeated fuse failures usually signal an underlying short or defective coil that must be repaired.

3. Where is the ignition coil fuse typically located?

The ignition coil fuse is commonly located in the engine bay or interior fuse box, labeled as IGN, IG COIL, or EFI, depending on the vehicle design. The user manual or service documentation provides the exact position and rating.