Automotive Fuse Box Insulators Heat-Resistant Protection for Circuits

News 2025-10-31

Automotive fuse box insulators play a crucial role in safeguarding electrical circuits by providing heat-resistant barriers that prevent overheating and potential failures. These components are essential in modern vehicles, where complex electrical systems demand reliable protection against thermal stress. By insulating fuse boxes, they help maintain optimal performance and longevity, reducing the risk of short circuits or fires caused by excessive heat. This protection is vital as vehicles incorporate more electronic features, ensuring safety and efficiency in various driving conditions.

Applications in Automotive Systems

In automotive engineering, fuse box insulators are widely used in battery management systems, lighting circuits, and engine control units. They are particularly important in electric and hybrid vehicles, where high-voltage components generate significant heat. For instance, in electric cars, these insulators protect sensitive wiring in the fuse box from thermal damage during rapid charging or heavy acceleration. Additionally, in traditional combustion engines, they shield circuits in the engine compartment from heat radiated by exhaust systems, enhancing reliability in extreme temperatures and harsh environments.

Performance Advantages

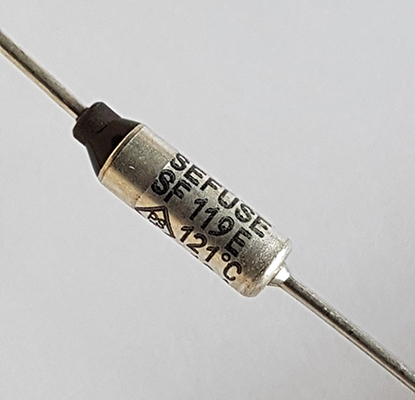

Heat-resistant insulators offer superior thermal stability, with materials like ceramic or advanced polymers withstanding temperatures up to 200°C without degrading. This durability ensures consistent electrical isolation, minimizing conductivity risks and extending component lifespan. Their design also reduces weight and space requirements, improving vehicle efficiency. Moreover, these insulators enhance safety by preventing arc faults, which can occur in high-heat scenarios, thus protecting both the vehicle’s electronics and occupants from potential hazards.

Frequently Asked Questions

1. What materials are commonly used in fuse box insulators?

Answer: Common materials include ceramics, silicone rubber, and high-temperature plastics, chosen for their excellent thermal resistance and electrical insulation properties.

2. How do these insulators improve vehicle safety?

Answer: They prevent overheating-induced failures that could lead to short circuits or fires, thereby reducing accident risks in automotive electrical systems.

3. Can fuse box insulators be replaced easily?

Answer: Yes, most are designed for straightforward replacement during routine maintenance, ensuring quick and cost-effective upgrades when needed.