Battery Box Off-Road Trucks Features Rugged Design For Extreme Conditions

News 2025-11-17

Battery box off-road trucks features rugged design extreme conditions are reshaping how electrical power is stored and protected in punishing environments. These enclosures shield high-capacity batteries from shock, moisture, mud, and corrosive road debris while keeping electrical connections secure and serviceable. For fleets operating in mining, forestry, military support, construction, and desert logistics, the battery box has become a core component that directly influences vehicle uptime, power stability, and safety compliance.

Rugged Mechanical Design For Harsh Terrains

A purpose-built off-road truck battery box uses high-strength steel or thick-gauge aluminum with reinforced welds and internal bracing to withstand constant vibration and chassis flex. Impact-resistant corner guards, recessed latches, and protected hinge systems reduce the risk of mechanical damage when the vehicle encounters rocks, ruts, or unpaved work sites. Integrated rubber mounts and anti-vibration pads help isolate the battery pack from shocks that can crack cases or loosen terminals, preserving the integrity of internal cells and busbars. Many designs also incorporate structural ribs and stiffeners, enabling the enclosure to handle the weight of large-format batteries used in hybrid or auxiliary power systems.

Environmental Protection And Thermal Management

To perform in snow, desert heat, river crossings, and heavy dust, off-road battery boxes rely on advanced sealing strategies. Gasketed lids, compression latches, and IP-rated cable glands block water, mud, and fine particles from entering the enclosure, reducing corrosion of terminals and connectors. Drain ports or one-way vents remove condensation while preventing splash intrusion. Thermal management is equally important: reflective coatings, passive ventilation channels, and optional integrated heaters or cooling plates help maintain optimal cell temperature. Stable thermal conditions extend battery cycle life, minimize capacity loss in cold climates, and reduce the risk of overheating during high-current discharge common in winching, PTO drives, or emergency power use.

Electrical Safety, Serviceability, And Integration

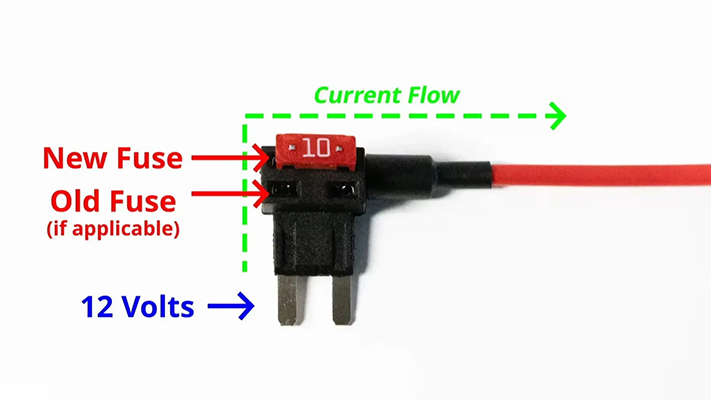

A well-engineered off-road battery box simplifies integration with the truck’s electrical architecture while meeting safety standards. Internal layouts separate high-current busbars, fuses, and monitoring electronics to reduce short-circuit risk. Clearly labeled terminals, color-coded harness routing, and protected fuse blocks support fast troubleshooting in the field. Many enclosures accommodate battery management systems, shunts for current sensing, and telematics modules that report voltage, state of charge, and temperature to fleet dashboards. Service-friendly features such as quick-release covers, slide-out trays, and external disconnect switches allow technicians to isolate power and replace packs without removing adjacent components, improving maintenance efficiency and minimizing downtime for work-critical vehicles.

Application Scenarios And Performance Advantages

Off-road truck battery boxes show their value in demanding scenarios where electrical failure is not acceptable. In open-pit mining, trucks operate around the clock under heavy vibration and conductive dust; rugged enclosures protect high-current starting batteries and auxiliary packs for lighting, hydraulic systems, and monitoring electronics. In utility and telecom support fleets, battery boxes host deep-cycle batteries powering cranes, inverters, and communication gear at remote sites. Military logistics trucks require low-visibility, EMI-conscious designs with secure locking mechanisms for mission-critical power. Across these applications, the key performance advantages include longer battery lifespan, reduced unplanned outages, higher resistance to environmental damage, and consistent power delivery for both engine starting and auxiliary loads.

Key Questions And Short Answers

1. How does a rugged battery box improve off-road truck uptime?

A robust enclosure protects batteries from vibration, moisture, and impact, which lowers failure rates and reduces emergency service calls, keeping vehicles operational longer in remote locations.

22. What features matter most when selecting an off-road battery box?

Buyers should focus on material strength, sealing performance, vibration isolation, thermal management options, and layout compatibility with existing electrical systems and monitoring hardware.

33. Which industries benefit most from heavy-duty battery box solutions?

Mining, oil and gas, construction, agriculture, emergency response, and defense sectors gain significant benefits because their fleets operate in extreme environments where stable electrical power is essential for mission success.