Battery Box Solutions for Heavy-Duty Commercial Vehicles in High-Frequency Operation

News 2025-11-17

Battery box commercial vehicles heavy-duty build frequent use scenarios demand a different engineering mindset than light-duty automotive applications. Fleets operating logistics trucks, construction machinery, municipal buses, or airport ground support equipment require energy storage enclosures that withstand continuous vibration, repeated thermal cycling, and daily charging routines. A well-designed battery box becomes part of the safety system, the thermal management chain, and the vehicle uptime strategy, not just a container.

Key Application Scenarios in Commercial Fleets

Battery box systems in heavy-duty commercial vehicles are tailored to demanding use profiles. Long-haul delivery trucks need large-capacity enclosures with optimized weight distribution along the chassis to maintain stability and axle load limits. Urban buses and refuse trucks operate in stop-and-go cycles, where frequent acceleration and regenerative braking generate substantial heat, making robust ventilation and thermal paths inside the box crucial. In mining and construction vehicles, the enclosure must resist rock impacts, dust ingress, and high humidity, often requiring IP67 or higher sealing, reinforced lids, and corrosion-resistant finishes. Airport and port tractors see intense daily usage with short downtime windows, pushing the need for battery boxes that support ultra-fast charging and easy modular replacement to keep operations running around the clock.

Structural Design and Safety Performance Advantages

From a structural standpoint, heavy-duty battery boxes are engineered with high-strength steel or aluminum alloys, combined with precisely formed welds and brackets to manage continuous vibration on rough roads. Strategic use of internal partitions, foam inserts, and cell frames protects individual modules from impact while preventing movement under shock loads. Safety performance is enhanced through integrated pressure relief paths, flame-retardant materials, and dedicated channels that direct gas venting away from passengers and critical components. For high-voltage systems, the enclosure incorporates creepage and clearance distances that meet automotive and industrial standards, alongside high IP-rated seals that block water, salt spray, and dust. These features reduce the risk of short circuits, thermal runaway spread, and corrosion-related failures in long-term field operation.

Thermal Management and Electrical Interface for Frequent Use

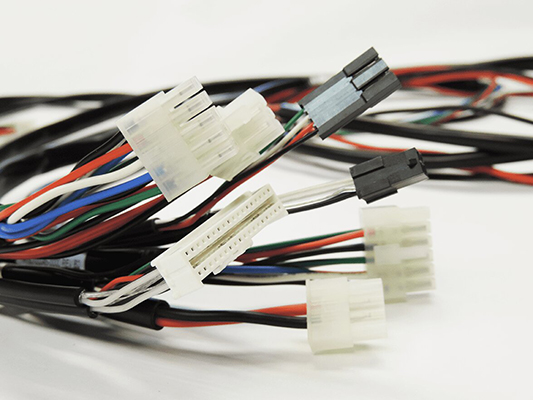

In high-frequency charge and discharge cycles, thermal control inside the battery box becomes a core performance factor. Enclosures can integrate liquid-cooling plates, embedded coolant channels, or forced-air ducting that connects to the vehicle’s HVAC or dedicated cooling unit. Temperature sensors distributed across modules feed data to the battery management system, enabling active balancing and targeted cooling during fast charging. Electrical interfaces are designed for high current ratings with low contact resistance, using robust busbars, sealed high-voltage connectors, and clearly routed low-voltage harnesses for diagnostics and communication. Quick-disconnect features support rapid maintenance or module swap without compromising safety. Through optimized thermal paths and electrical layout, the battery box supports intensive daily operation while maintaining stable cell temperatures and extending cycle life.

Customization, Maintenance, and Future-Ready Integration

Commercial vehicle platforms often require customized battery box dimensions, mounting points, and ingress/egress layouts to match frame rails, suspension geometry, and body configurations. Modular enclosure concepts allow fleet operators to scale capacity by adding or removing standard-sized boxes across different vehicle models. Maintenance efficiency is improved through hinged or slide-out designs, external service ports, and clear labeling of isolation switches and diagnosis connectors. For OEMs preparing for future technologies, the battery box is designed with space and interface provisions for higher energy density cells, upgraded cooling loops, and auxiliary electronics such as DC/DC converters or telematics units. This future-ready design approach protects investment and ensures the enclosure remains compatible with upcoming battery chemistries and stricter safety regulations.

1. How does a battery box improve heavy-duty vehicle safety?

A properly engineered battery box isolates high-voltage components, manages impact loads, controls thermal events, and routes gas venting away from occupants, significantly lowering electrical and fire risks during frequent use.

2. Why is thermal management inside the battery box so important?

High-frequency charging and discharging generate heat that accelerates cell aging; effective cooling and temperature monitoring keep cells within an optimal range, extending service life and maintaining stable performance.

3. What features matter most for fleet operators?

Fleet operators prioritize robust enclosures with high ingress protection, modular capacity options, fast maintenance access, and interfaces that support quick diagnostics, all of which help maximize vehicle uptime and total cost efficiency.