Bespoke Wire Harness Assemblies for Vintage and Classic Car Restoration Electricals

News 2025-10-31

In the realm of automotive restoration, bespoke wire harness assemblies play a pivotal role in reviving the electrical systems of vintage and classic cars. These custom-engineered components are tailored to meet the specific needs of older vehicles, ensuring compatibility with original designs while incorporating modern materials and technologies. As enthusiasts and professionals tackle the challenges of restoring cars from eras like the 1950s to the 1980s, wire harnesses provide the backbone for reliable electrical performance. This approach not only preserves the authenticity of classic automobiles but also enhances safety and functionality, making it an indispensable part of any restoration project.

Performance Advantages

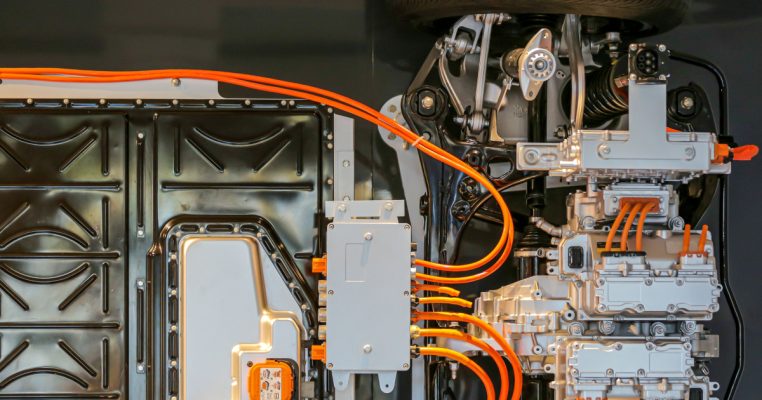

Wire harness assemblies offer significant performance benefits that set them apart in vintage car restorations. Crafted with high-quality, durable materials such as cross-linked polyethylene or silicone insulation, these harnesses resist heat, moisture, and vibration better than original factory components. This results in improved electrical conductivity and reduced risk of shorts or failures, which are common in aging vehicles. Additionally, custom designs allow for precise routing and connector configurations, minimizing weight and space issues while optimizing energy efficiency. Such enhancements ensure that restored cars not only look authentic but also perform reliably on the road, meeting contemporary safety standards without compromising historical integrity.

Application Scenarios

Bespoke wire harnesses find extensive use in various aspects of vintage and classic car restoration. For instance, in dashboard and lighting systems, they facilitate seamless integration of modern LEDs or upgraded gauges while maintaining the original wiring layout. In engine compartments, these assemblies support the revival of complex ignition and fuel injection systems, ensuring compatibility with both carbureted and electronic setups. Restoration shops often employ them in full vehicle rewires, where they address corrosion and outdated materials, extending the lifespan of electrical components. Whether for concours-level restorations or daily drivers, these harnesses adapt to diverse scenarios, from track events to museum displays, providing tailored solutions that enhance both aesthetics and operational reliability.

Frequently Asked Questions

1. What materials are used in bespoke wire harnesses?

They are constructed from high-grade copper conductors and advanced insulating materials like PVC or Teflon, chosen for durability and resistance to automotive environments.

2. How do custom harnesses improve safety in classic cars?

By incorporating color-coded wires and secure connectors, they reduce the risk of electrical faults and fires, ensuring compliance with modern safety regulations.

3. Can these harnesses be installed by amateurs?

While basic installation is possible for experienced hobbyists, professional assistance is recommended to ensure proper fitting and avoid potential electrical issues.