Compact Thermal Fuse Solution Enhances Automotive Safety and Layout Flexibility

News 2025-11-27

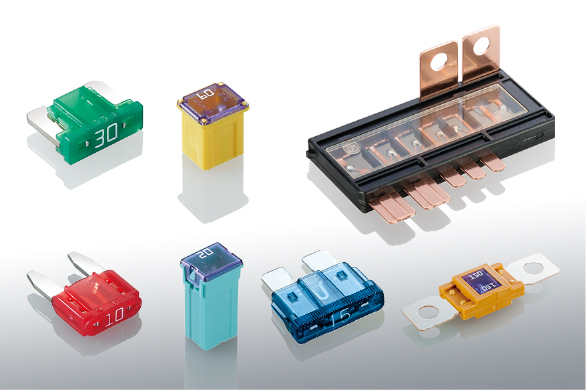

Compact-size thermal fuses are becoming a key protection component in next-generation vehicles, where dense electronic architectures and elevated power levels raise the risk of overheating. By interrupting current once a defined temperature is reached, these fuses prevent damage to wire harnesses, power modules, and battery systems. Their minimized footprint and standardized lead spacing allow easy integration into existing platforms while supporting higher component density in control units and junction boxes.

Flexible Installation in Constrained Automotive Spaces

Modern vehicles pack ECUs, sensors, and power electronics into extremely tight locations, from instrument panels to door modules. The compact thermal fuse format enables direct mounting on crowded PCBs or inline placement within harness branches, even near connectors or actuators. Axial and radial lead options, as well as SMD-compatible variants, give design engineers freedom to orient the fuse according to airflow, mounting height, or proximity to heat sources. This flexibility supports modular platform designs and simplifies global variants of the same vehicle architecture.

Performance Characteristics and Safety Compliance

Automotive-grade thermal fuses are engineered for precise opening temperatures, narrow tolerance bands, and stable characteristics across the full ambient range typically demanded by under‑hood and cabin applications. Fast response time, low contact resistance, and high interrupt rating enable dependable operation in 12 V, 24 V, and emerging 48 V systems. Compliance with standards such as AEC‑Q200, UL, and IEC helps OEMs align protection concepts with functional safety targets, particularly in high-power loads like heated seats, blower motors, pumps, and PTC heaters.

Key Application Scenarios in Vehicle Electronics

In internal combustion and hybrid platforms, compact thermal fuses are typically installed in heater circuits, audio amplifiers, infotainment units, and LED headlamp drivers to prevent thermal runaway under fault conditions. In battery electric vehicles, they play a growing role protecting on-board chargers, DC‑DC converters, battery junction boxes, and charging inlet assemblies. Integrating the fuse close to high-risk hotspots, such as power MOSFET clusters or magnetic components, ensures fast thermal coupling and limits damage to nearby circuitry. This targeted protection strategy reduces repair costs and supports warranty performance.

Design Considerations, Integration Tips, and Q&A

When selecting a compact thermal fuse, engineers must match opening temperature to the worst-case thermal profile of the application while ensuring adequate safety margin above normal operating levels. Proper derating, attention to thermal coupling, and validation under real load cycles are vital to avoid nuisance trips or delayed operation. Combining the thermal fuse with PTC thermistors, temperature sensors, or intelligent power switches can create layered protection strategies tuned to the system’s fault tree.

1What distinguishes a compact automotive thermal fuse?

A compact automotive thermal fuse offers a small footprint, precise opening temperature, and high interrupt capability tailored to tight spaces in ECUs, harnesses, and modules while meeting automotive qualification standards.

2Where is a compact thermal fuse typically placed in a car?

It is commonly installed near heat-generating components such as heater elements, power stages, LED drivers, chargers, or battery junctions, either on the PCB or inline within dedicated harness segments.

3How does fuse size influence vehicle design flexibility?

A smaller fuse allows denser PCB layouts, easier routing in harness branches, and more freedom to position protection close to thermal hotspots, enabling compact modules and scalable platform architectures.