Consistent-Performance Thermal Fuse Ensures Stable and Safe Circuit Protection in Electronics

News 2025-11-27

Consistent-performance thermal fuses play a decisive role in modern electronic protection strategies. By combining precise temperature calibration and fast response to overheat events, these components interrupt fault currents before damage spreads to semiconductors, PCBs, or enclosures. Compared with resettable protectors, a thermal fuse provides a clear one-time cut-off once the rated temperature is reached, helping design engineers meet stringent safety regulations, improve product lifetime, and reduce warranty risk.

Working Principle and Performance Characteristics

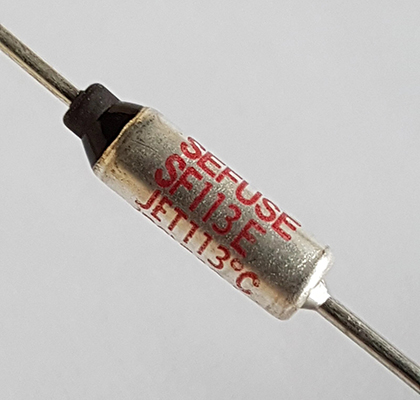

A consistent-performance thermal fuse contains a temperature-sensitive alloy or organic pellet precisely formulated to melt or deform at a specified opening temperature. Under normal operating conditions, the fuse maintains low resistance and minimal power loss, supporting high efficiency in compact consumer electronics, power supplies, and motor drives. When abnormal heat caused by overload, stalled motors, or component failure raises the internal temperature, the fusible element separates, permanently opening the circuit. Key parameters include rated functioning temperature, holding temperature, rated current, interrupting capacity, and insulation resistance, all of which must be carefully matched to the application profile.

Key Application Scenarios in Modern Electronics

Consistent-performance thermal fuses are widely used in switching power adapters, battery packs, LED drivers, household appliances, HVAC actuators, and industrial automation modules. In power adapters and chargers, they protect plastic housings and nearby components from overheating caused by surge events or shorted switching devices. In lithium-ion battery packs, they are often placed near cells or busbars to disconnect the pack when abnormal thermal runaway conditions begin to develop, enhancing user safety and helping products comply with transportation and battery safety standards. In appliances such as coffee makers, hair dryers, and washing machines, thermal fuses protect heating elements and motors, preventing fire hazards and minimizing costly field failures.

Benefits in Safety, Compliance, and System Design

Using a consistent-performance thermal fuse helps manufacturers align designs with safety norms such as UL, IEC, and regional appliance standards. Accurate, repeatable opening temperatures reduce the risk of nuisance tripping while still reacting quickly to true fault conditions. The permanent open-circuit behavior supports clear post-failure diagnostics: once activated, the component must be replaced, signaling that the product experienced abnormal stress. This simplifies safety assessments and maintenance procedures. From a design perspective, compact radial and axial packages enable easy placement close to heat sources, and low internal resistance minimizes temperature rise during normal operation, supporting dense layouts in high-efficiency systems.

Selection Considerations and Integration Tips

Effective circuit protection depends on choosing a thermal fuse whose characteristics match the thermal profile of the end product. Engineers should evaluate the maximum steady-state temperature near the target mounting area, the worst-case fault temperature, ambient conditions, and expected inrush current. The functioning temperature must sit safely above the maximum normal operating temperature but below the temperature that could damage insulation, plastics, or cells. Proper mechanical mounting is equally important: good thermal coupling to the monitored component, secure leads, and avoidance of excessive soldering heat preserve calibration and long-term stability. Combining a thermal fuse with current fuses, PTC thermistors, or thermal switches can create layered protection in demanding industrial and automotive environments.

Common Questions on Thermal Fuse Application

1How is a thermal fuse different from a conventional current fuse?

A thermal fuse reacts primarily to temperature rather than current alone. It opens when the internal temperature exceeds the specified value, even if the current remains within rated limits, making it ideal for overheating caused by blocked airflow or failed control circuits.

2Can a thermal fuse be reset after it opens?

No. Once a consistent-performance thermal fuse operates, the internal element is permanently separated. The device must be replaced during service, which helps confirm that an abnormal thermal event occurred.

3Where should a thermal fuse be placed in a circuit?

The fuse should be mounted as close as possible to the most critical heat source, such as a transformer winding, heater, motor coil, or battery cell group, ensuring accurate sensing of real surface temperature and fast interruption in fault conditions.