Corrosion-Proof Thermal Fuse Ensures Durability in Humid Vehicle Environments

News 2025-11-27

Modern vehicles operate in increasingly demanding climates, where moisture, salt spray, and temperature cycling place severe stress on every electronic protection device. A corrosion-proof thermal fuse specifically engineered for humid vehicle environments helps safeguard wiring harnesses, battery packs, LED lighting modules, HVAC blowers, and on-board chargers. By preventing overtemperature damage even under long-term exposure to condensation and road salt, this component supports higher system uptime, reduced maintenance, and extended service life of critical automotive subsystems.

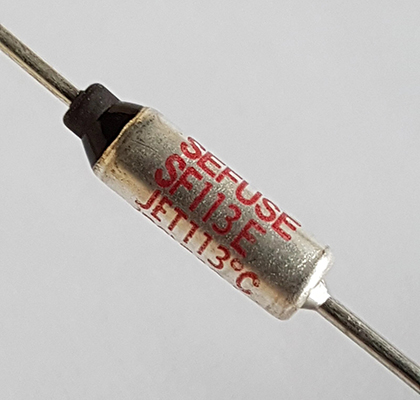

Engineering Design Tailored to Harsh Humidity

The corrosion-proof thermal fuse combines a sealed housing, moisture-resistant lead plating, and thermally stable internal materials that maintain predictable opening characteristics after prolonged humidity exposure. Protective coatings and carefully selected alloys limit galvanic reactions and prevent oxidation at contact points. As a result, resistance drift is minimized and trip temperature remains within a narrow tolerance band, even after thousands of hours in high-humidity and high-temperature storage tests. This stability is vital in vehicles operating in coastal regions, tropical climates, or areas where de-icing salt is used extensively on roads.

Performance Advantages in Vehicle Safety Systems

In electric and hybrid vehicles, the thermal fuse is often positioned near high-current busbars, DC/DC converters, battery junction boxes, and auxiliary heaters. When abnormal heat builds up due to overload, blocked airflow, or control failure, the fuse opens the circuit and prevents thermal runaway. The corrosion-proof design avoids performance degradation caused by moisture penetration, which could otherwise delay operation or cause intermittent behavior. Consistent interruption capability under IEC and automotive OEM standards helps engineers meet stringent functional safety targets, especially in systems classified under ISO 26262.

Key Application Scenarios in Humid Vehicle Environments

Typical application scenarios include engine compartment control units subjected to temperature shocks and spray water, underbody lighting and sensor modules exposed to road splash, and battery cooling fans placed in confined, condensation-prone spaces. The corrosion-proof thermal fuse suits plug-in charging inlets, cabin comfort electronics near evaporators, and seat heating circuits where moisture and organic contaminants can accelerate corrosion. By offering stable performance in these locations, the component allows designers to shrink protective margins, optimize thermal design, and use lighter enclosures while still achieving required lifetime targets under severe humidity cycles.

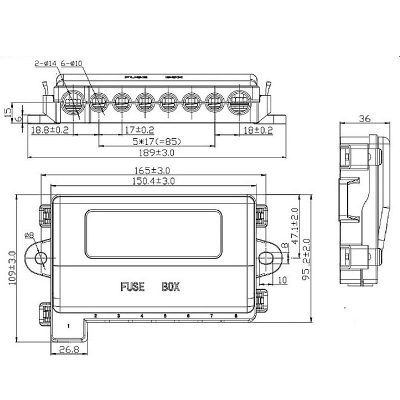

Integration, Standards, and Design-In Considerations

The device can be supplied in radial leaded, axial, or surface-mount formats, enabling integration into PCBs, wire harnesses, or modular assemblies. Automotive-grade versions follow AEC-Q200 or equivalent qualification regimes, including thermal shock, salt spray, and biased humidity testing. Designers should place the thermal fuse in direct thermal contact with the primary heat source while ensuring adequate creepage and clearance distances for the system voltage level. Proper derating, combined with accurate simulation of worst-case ambient conditions, ensures that the selected opening temperature and current rating provide both robust protection and low nuisance-trip probability.

1What range of vehicles benefits from a corrosion-proof thermal fuse?

Passenger cars, commercial trucks, construction machinery, and electric buses all benefit, especially when operating in regions with high humidity, heavy rainfall, or frequent road salt exposure.

2How does corrosion resistance enhance long-term fuse performance?

By preventing oxidation and electrochemical reactions on internal contacts and leads, corrosion resistance keeps the trip temperature and resistance characteristics stable throughout the vehicle lifetime.

3Which standards should engineers consider when selecting this type of thermal fuse?

Engineers typically reference AEC-Q200, IEC safety standards for thermal links, as well as OEM-specific environmental and functional safety specifications related to ISO 26262.