Safety-Certified Thermal Fuse Enables High-Integrity Automotive Circuit Protection Worldwide

News 2025-11-27

Safety-Certified Thermal Fuse Complies With Global Automotive Protection Standards

Regulatory Compliance and Design Philosophy

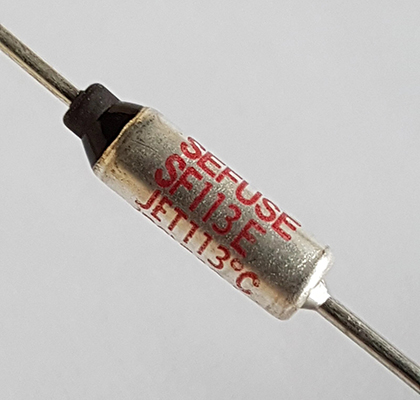

A safety-certified thermal fuse specifically designed for automotive electronics must align with stringent global regulations such as AEC-Q200, IATF 16949, and ISO 26262 functional safety frameworks. This fuse integrates precise melting-alloy technology and encapsulation structures that ensure predictable opening behavior at a defined temperature threshold, even under severe vibration, shock, and thermal cycling. Automotive engineers gain a predictable last-resort protection element that disconnects the circuit before overheating escalates into smoke, fire, or irreversible damage to power modules. Its compact footprint and lead-free construction support eco-efficient vehicle architectures and comply with RoHS and ELV directives.

Key Performance Advantages in Harsh Environments

The thermal fuse offers tight trip temperature tolerance, low internal resistance, and exceptional long-term stability under repetitive load pulses. Its fast response to abnormal thermal rise protects MOSFET-based power stages, DC-DC converters, and on-board chargers from thermal runaway. High dielectric strength between terminals and body enhances insulation integrity in dense PCBs, while low contact resistance minimizes power loss in high-current lines. The component maintains performance across extended temperature ranges common in engine bay and underfloor battery placements, supporting high humidity, salt-mist exposure, and mechanical stress found in commercial vehicles and off-road platforms.

Automotive Application Scenarios and Integration

This safety-certified thermal fuse is widely applied in traction battery packs, battery management systems, electric power steering, ABS/ESC modules, HVAC blowers, and seat heating controllers. In xEV battery systems it protects cell-balancing circuits, current sensors, and relay driver boards from localized overheating caused by connector failures or PCB hotspots. Within infotainment units and ADAS controllers, it helps safeguard SoC power rails, backlight drivers, and USB power ports where high ambient temperatures and continuous operation elevate risk. The fuse can be designed into primary protection paths or act as a secondary safeguard in combination with PTCs and electronic protection ICs.

Design-In Considerations and System-Level Benefits

Engineers typically place the thermal fuse close to heat sources such as power semiconductors, inductors, or high-current busbars to guarantee accurate thermal coupling. Multiple rating options allow coordination with line fuses and circuit breakers, ensuring selective opening only in genuine overheating conditions. The component simplifies safety case documentation, as its approvals from recognized testing agencies help demonstrate compliance during OEM audits. By preventing catastrophic failure events, the fuse reduces warranty claims, supports higher power density designs, and facilitates the move toward centralized domain controllers and zone-based architectures in next-generation vehicles.

FAQ: Safety-Certified Automotive Thermal Fuses

1. Typical Operating Temperature Range

The thermal fuse generally supports ambient conditions from -40°C to +125°C, with specific opening temperatures calibrated for the target application window.

2. Compatibility With EV High-Voltage Systems

Dedicated high-voltage variants can be implemented on auxiliary circuits in 400 V and 800 V battery platforms, provided creepage and clearance rules are respected in the PCB layout.

3. Maintenance Requirements In Vehicle Lifetime

The fuse is a non-resettable component; under normal operation it requires no maintenance and is only replaced if an overtemperature event has triggered permanent opening.