Corrosion-Resistant Material Thermal Fuse Enhances Safety in Wet Environments

News 2025-11-27

Corrosion-resistant material thermal fuses are engineered to maintain stable performance even when exposed to moisture, salt spray, and condensation. In demanding electrical and electronic systems, especially where humidity and splashing water are unavoidable, traditional fuses can suffer from oxidation, increased contact resistance, and unpredictable opening behavior. By using specialized metals, surface treatments, and sealed constructions, a corrosion-resistant thermal fuse sustains its calibrated trip temperature and current-carrying capacity over long service periods. This makes it a strong choice for safety-critical circuits exposed to wet or chemically aggressive environments.

Key Structure and Material Characteristics

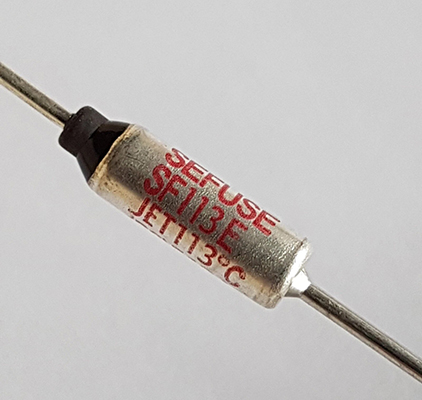

Corrosion-resistant thermal fuses typically combine a temperature-sensitive pellet or organic element, a fusible alloy, and protected metal leads enclosed in a moisture-tolerant housing. The leads and internal components use corrosion-resistant alloys or plated copper that slow electrochemical reactions in the presence of water, electrolytes, and cleaning fluids. Sealing techniques such as glass-to-metal, epoxy, or crimped metal sleeves reduce the penetration of vapor and droplets. This robust construction stabilizes electrical contact points, prevents swelling or deterioration of the thermal element, and keeps the fuse’s opening temperature within its specified tolerance window during its entire lifetime.

Performance Advantages in Wet Conditions

The primary performance benefit is predictable thermal response under persistent humidity and intermittent immersion. Even after repeated condensation cycles, the fuse maintains low contact resistance, avoiding undesired heating that could shift the trip point. Corrosion-resistant surfaces help avoid metallic migration and leakage currents on densely populated PCBs, supporting safe creepage and clearance distances. These fuses also show improved mechanical integrity against rust-induced cracking or lead fracture, which is crucial in applications subject to vibration. Stable I²t characteristics and certified compliance with safety standards such as UL or IEC allow design engineers to accurately coordinate the fuse with upstream circuit breakers and downstream loads.

Typical Application Scenarios

Wet and harsh environments are common in household appliances, outdoor power equipment, and industrial systems. In washing machines, dishwashers, water heaters, and beverage dispensers, the thermal fuse protects heating elements and control boards located near water paths or steam. In HVAC units, dehumidifiers, and heat pumps, it guards motors and compressors exposed to condensate. Outdoor LED drivers, EV charging accessories, agricultural pumps, and marine electronics rely on corrosion-resistant fuses to withstand rain, fog, salt spray, and washdown cleaning. These devices also suit medical sterilization equipment and laboratory instruments where frequent chemical sanitization can rapidly corrode standard fuse bodies and leads.

Design Considerations and Selection Tips

When selecting a corrosion-resistant material thermal fuse, engineers should evaluate nominal opening temperature, holding current, rated voltage, and environmental test data. Parameters like salt-spray duration, damp-heat cycling, and insulation resistance after aging help predict field performance. Matching the fuse’s temperature rating to the maximum safe component temperature prevents nuisance tripping while still safeguarding against runaway heating. Proper PCB layout, conformal coating, and strategic placement away from direct water jets further increase robustness. Collaborating with fuse manufacturers to review derating curves and failure mode data helps ensure the device opens safely and does not reset, satisfying regulatory safety requirements and long-term warranty expectations.

Common Questions About Corrosion-Resistant Thermal Fuses

1How does corrosion resistance improve fuse lifespan?

Corrosion-resistant metals and seal structures slow oxidation and prevent moisture from degrading contacts, so the fuse maintains accurate trip behavior over years of exposure to humidity and condensation.

2Where are these fuses most frequently used?

They are widely used in wet-area appliances, HVAC systems, outdoor power supplies, marine equipment, and industrial washdown environments where ordinary fuses would corrode too quickly.

3Can they replace standard thermal fuses directly?

In many cases yes, as long as voltage, current, and opening temperature ratings are equivalent, and the mechanical dimensions match the existing PCB footprint or lead spacing.