Corrosion Resistant Surface Auto Fuse Enabling Stable Long Term Vehicle Operation

News 2025-12-08

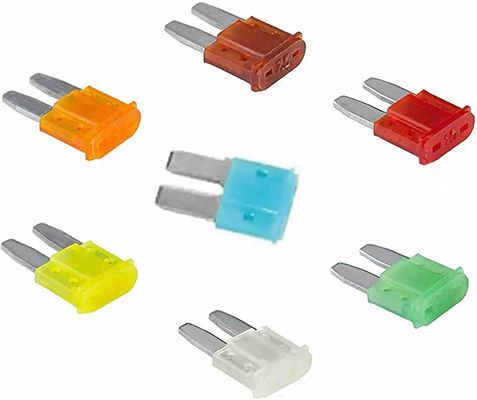

Corrosion resistant surface auto fuses play a decisive role in modern automotive electrical protection. Designed to withstand harsh under‑hood environments, road salt, moisture, and continuous thermal cycling, these components help maintain circuit integrity over many years of vehicle operation. By combining optimized alloy elements, protective platings, and robust encapsulation, they safeguard sensitive control units, lighting circuits, comfort electronics, and high-current loads in passenger cars, commercial trucks, and off‑road equipment.

Key Performance Characteristics

High‑grade surface treatments significantly slow chemical degradation at fuse terminals and contact areas. Stable contact resistance supports accurate current rating, minimizing nuisance trips and overheating. Tight manufacturing tolerances keep the melting time‑current curve consistent, which is vital for CAN bus modules, infotainment systems, and advanced safety electronics. Low internal resistance helps reduce energy loss and heat generation in dense fuse boxes, improving overall electrical efficiency and extending component lifespan.

Automotive Application Scenarios

These fuses are widely deployed in engine compartment junction boxes, cabin fuse panels, battery distribution units, and auxiliary power modules. In coastal regions and snow‑belt markets, road salt and humidity accelerate corrosion on standard fuse blades, often causing intermittent faults. Corrosion resistant versions maintain dependable contact in trailer circuits, electric power steering, start‑stop systems, and auxiliary heaters. In commercial fleets and construction vehicles, extended service intervals demand fuses that continue operating safely after thousands of hours of vibration, dust exposure, and temperature extremes.

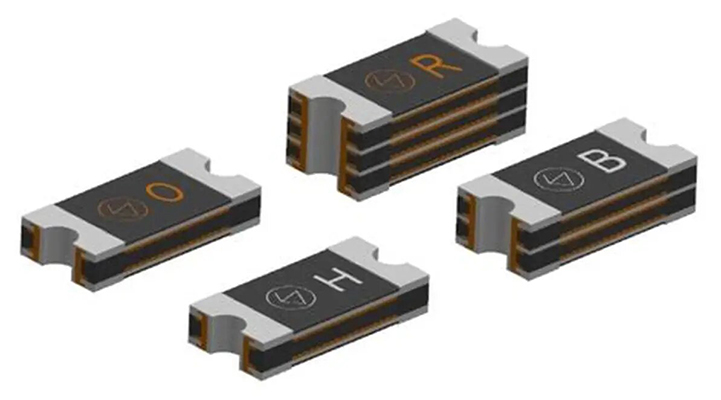

Design, Materials, and Compliance

The fuse element and terminals typically employ copper or copper alloys with anti‑corrosive plating such as tin or nickel, combined with engineered plastics rated for high temperature and chemical resistance. Encapsulation designs limit ingress of moisture and contaminants while supporting automated surface mounting or plug‑in assembly. Products usually comply with ISO, SAE, and RoHS requirements, enabling use by global OEMs and aftermarket manufacturers. Consistent quality documentation, lot traceability, and compatibility with standard fuse holders simplify integration into existing vehicle architectures.

Selection, Installation, and Maintenance

Engineers should select current and voltage ratings based on peak load, ambient temperature, wiring size, and fault profile. Using corrosion resistant fuses in exposed locations such as engine bays and chassis rails helps prevent hidden contact failures. During installation, clean mating surfaces and proper insertion depth maintain low contact resistance. In maintenance operations, replacing conventional corroded fuses with corrosion resistant variants can resolve intermittent lighting or accessory issues while reducing future service visits.

1. What benefits do corrosion resistant auto fuses provide in coastal regions?

They prevent oxidation on terminals, keeping contact resistance stable and reducing unexpected circuit interruptions caused by salt and moisture.

2. Are these fuses suitable for heavy‑duty commercial vehicles?

Yes, their enhanced plating, robust housings, and stable time‑current behavior suit trucks, buses, and construction equipment exposed to vibration and harsh environments.

3. Do corrosion resistant fuses improve overall vehicle uptime?

By reducing contact failures, overheating, and nuisance fuse blows, they help extend service intervals and support consistent vehicle availability over long‑term use.