Current Fuse Durability in Extreme Temperature Engine Bay Conditions

News 2025-10-24

Fuses play a vital role in safeguarding electrical systems within vehicles, particularly in the engine bay where conditions are severe. Temperatures can fluctuate dramatically, from freezing cold to scorching heat, posing significant challenges to component longevity. As automotive technology advances, ensuring fuse reliability under these extremes is crucial for preventing failures that could lead to costly repairs or safety hazards. This discussion focuses on the durability aspects, drawing from industry standards and real-world applications to highlight how modern fuses are engineered to withstand such environments.

Environmental Challenges in Engine Bays

Engine bays expose fuses to a range of harsh conditions beyond just temperature, including vibrations, moisture, and chemical contaminants. Extreme heat can cause material degradation, such as melting or oxidation, while rapid temperature changes lead to thermal stress and potential cracking. In scenarios like high-performance engines or electric vehicles, fuses must endure cycles of intense heat during operation and cold exposure when idle. These factors collectively reduce fuse lifespan, necessitating designs that incorporate robust materials and protective coatings to maintain functionality over time.

Key Performance Enhancements for Durability

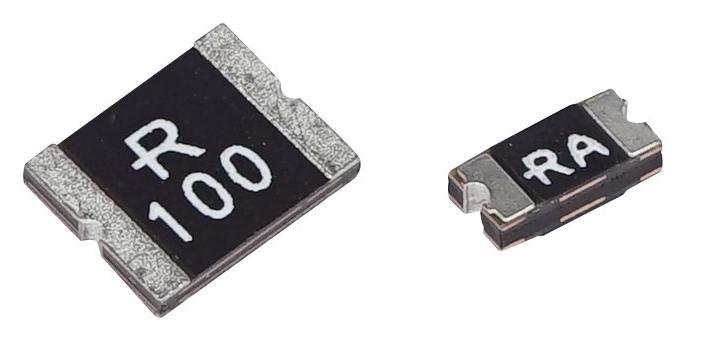

Modern fuse designs leverage advanced materials and engineering to boost resilience in extreme temperatures. For instance, ceramic-based fuses offer superior heat resistance, allowing them to operate effectively up to 200°C without compromising response times. In engine bay applications, such enhancements ensure quick interruption of overcurrent events while withstanding thermal shocks. Additionally, sealed constructions prevent ingress of oils and debris, extending service life in demanding settings like heavy-duty trucks or sports cars, where reliability directly impacts performance and safety.

Frequently Asked Questions

1. What factors most affect fuse durability in engine bays?

Answer: Temperature extremes, vibration, and exposure to chemicals are primary factors that can accelerate wear and reduce lifespan.

2. How do modern fuses improve on traditional designs?

Answer: They use high-temperature materials and better sealing to handle wider temperature ranges and environmental stresses more effectively.

3. What testing methods ensure fuse reliability?

Answer: Accelerated aging tests simulate real-world conditions, including thermal cycling and humidity, to predict long-term performance.