Durable Construction Thermal Fuse Ensures Long-Term Safety in Demanding Daily Environments

News 2025-11-27

Thermal fuses play a decisive role in safeguarding consumer and industrial electronics, interrupting current when abnormal heat threatens component integrity. A durable-construction thermal fuse is engineered to endure repeated thermal cycling, vibration, and mechanical stress that occur in daily use. By resisting fatigue and material degradation, it maintains accurate opening temperature over the full service life of appliances, power adapters, battery packs, LED drivers, and motor controllers.

Rugged Construction and Core Performance Features

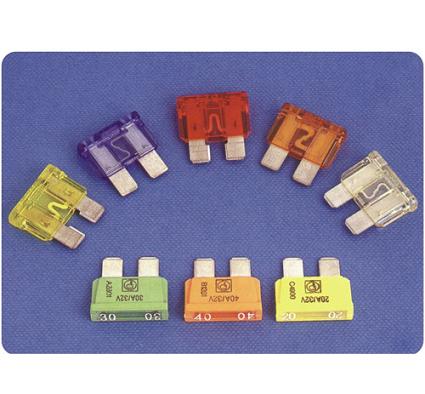

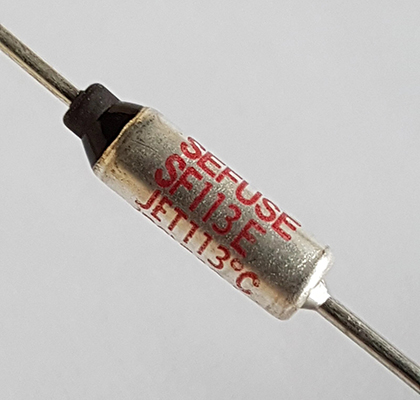

A durable-construction thermal fuse combines a robust metallic housing, corrosion‑resistant leads, and a precisely calibrated organic or alloy pellet. This structure retains dimensional stability under mechanical shock and persistent vibration, preventing drift in trip temperature. Tight tolerance manufacturing allows narrow opening ranges such as 72 °C, 115 °C, or Tf 240 °C, improving coordination with PTCs, NTCs, and overcurrent protection devices. Low contact resistance reduces self‑heating, while high insulation resistance at rated voltage supports safety compliance in compact assemblies.

Wear Resistance in Daily Consumer and Industrial Applications

In daily use, electronics face frequent on/off cycles, ambient temperature swings, and user‑induced impacts. A wear‑resistant thermal fuse maintains performance in coffee makers, hair dryers, rice cookers, refrigerators, and air purifiers where housing vibration and steam exposure are common. In office equipment, chargers, and set‑top boxes, stable construction prevents nuisance opening caused by minor temperature spikes. For industrial tools, pumps, fans, and lighting drivers, reinforced leads and crimp areas limit mechanical fatigue during installation, transportation, and maintenance.

Safety Compliance and Integration Benefits

Durable thermal fuses are typically tested to meet UL, VDE, and IEC standards, giving OEMs assurance of predictable behavior under overload, short‑circuit, and abnormal operation conditions. Consistent opening characteristics simplify thermal modeling, allowing designers to place the fuse near heating elements, transformers, MOSFETs, or battery cells without repeated redesign. Compact axial and radial packages streamline PCB layout in high-density power supplies and battery management systems, supporting high creepage and clearance distances required in Class II appliances.

Design Considerations and Long-Term Reliability

When specifying a thermal fuse focused on durability, engineers evaluate opening temperature, holding temperature, rated current, and maximum interrupting capacity in the actual application profile. Proper thermal coupling to hot spots via clips, clamps, or thermal pads ensures quick response during fault conditions. Use of high‑temperature leads and strong weld or solder joints reduces long‑term resistance drift and minimizes the risk of mechanical damage during assembly. These factors collectively enable stable protection performance across thousands of operating hours.

1、What devices benefit most from durable thermal fuses?

Household appliances, power adapters, LED drivers, HVAC controllers, industrial motors, and battery packs gain extended protection life and reduced service failures.

2、How does durable construction improve safety?

Robust materials preserve trip accuracy despite vibration and thermal stress, ensuring the fuse opens at the intended temperature and prevents overheating events.

3、Are these fuses suitable for compact electronic designs?

Yes, they are available in small axial or radial packages, allowing easy integration into space‑constrained PCBs while maintaining required safety clearances.