Efficient Wire Harness Configurations for Automotive Backup Camera and Display Electricals

News 2025-10-31

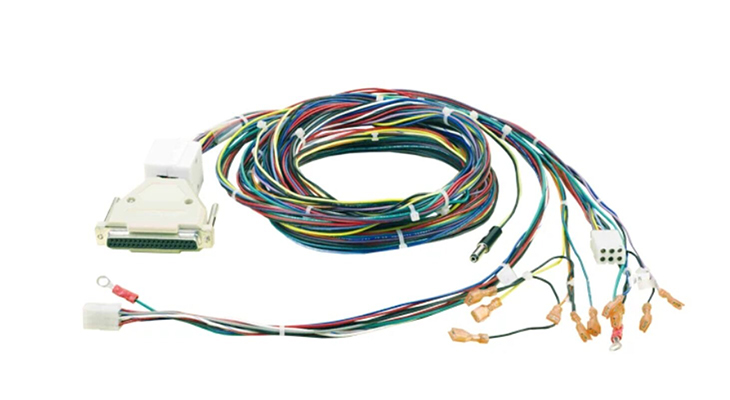

Wire harnesses play a crucial role in modern automotive systems, particularly in backup camera and display setups. These bundled assemblies of wires, connectors, and protective coverings ensure reliable electrical connections that enhance vehicle safety and functionality. In backup camera systems, wire harnesses transmit signals from the camera to the display unit, enabling drivers to see obstacles behind the vehicle. Efficient configurations minimize signal loss, reduce weight, and improve durability, which are essential for performance in harsh automotive environments. By optimizing wire routing and component selection, manufacturers can achieve better integration with vehicle electronics, leading to enhanced safety features and compliance with industry standards.

Key Components and Materials

Wire harnesses consist of several core elements that contribute to their efficiency in automotive applications. Conductors, typically made from copper for its excellent conductivity, are insulated with materials like PVC or cross-linked polyethylene to withstand temperature extremes and vibrations. Connectors and terminals ensure secure, low-resistance connections, while protective sheathing guards against moisture and abrasion. In backup camera systems, using high-quality components reduces the risk of signal interference, improving image clarity on displays. This focus on material selection and design enhances overall system reliability, making wire harnesses vital for maintaining performance in safety-critical features.

Optimizing Configurations for Enhanced Performance

Effective wire harness configurations involve strategic planning to meet specific automotive needs. For backup cameras and displays, compact designs with fewer bends reduce electrical resistance and heat buildup, extending component lifespan. In electric vehicles, configurations must accommodate high-voltage systems while integrating seamlessly with low-voltage camera circuits. Performance advantages include faster data transmission for real-time video feeds and reduced assembly time during manufacturing. By tailoring harness layouts to vehicle models, engineers can minimize space usage and improve accessibility, which is crucial in tight engine compartments. This approach not only boosts efficiency but also supports advancements in automotive safety technologies.

Frequently Asked Questions

1. What factors influence the choice of wire gauge in harnesses?

Wire gauge selection depends on current requirements and length to prevent overheating and voltage drop, ensuring reliable operation in backup systems.

2. How do sealed connectors benefit automotive wire harnesses?

Sealed connectors protect against water and dust, enhancing durability and preventing failures in exposed areas like rear bumpers.

3. What role does color-coding play in wire harness assembly?

Color-coding aids in quick identification during installation and maintenance, reducing errors and improving efficiency in complex automotive electrical systems.