Electric fan fuse protects engine cooling fan electrical circuits in demanding automotive environments

News 2025-11-17

An electric fan fuse in an engine cooling system is a compact protective device designed to interrupt power when current exceeds a safe threshold. Positioned in the cooling fan circuit between the battery supply and the fan motor, the fuse prevents overheating of wiring, damage to control modules, and potential fire hazards. In modern vehicles where engine bays are densely packed and temperatures run high, a correctly rated fuse is integral to dependable thermal management and long-term electrical safety.

Key Functions and Operating Principle

The electric fan fuse operates as a sacrificial link that opens when excessive current flows due to short circuits, seized fan motors, or wiring faults. The fuse element is calibrated to melt at a specific amperage, disconnecting the cooling fan from the power source before insulation or connectors are damaged. This rapid interrupt capability supports stable performance of the engine control unit and cooling fan relays. By isolating faults, the fuse also simplifies diagnostics, giving technicians a clear starting point when investigating overheating complaints or intermittent fan operation.

Application Scenarios in Engine Cooling Systems

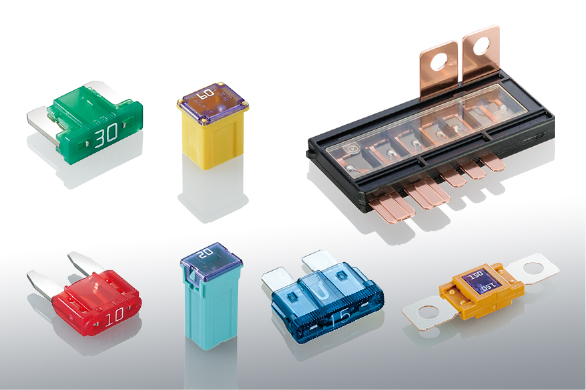

Electric fan fuses are used in passenger cars, commercial trucks, construction machinery, and agricultural vehicles where electric or electro-mechanical fans handle primary or supplemental cooling. Typical locations include under-hood fuse boxes, battery junction blocks, or dedicated power distribution modules. In vehicles equipped with dual or multi-speed fans, separate fuses may protect each fan motor or each speed circuit, ensuring localized protection. These devices are particularly important in stop-and-go traffic, towing, high ambient temperatures, and hybrid or start-stop systems where electric fans run frequently even when the engine is off.

Performance Advantages and Selection Considerations

High-quality electric fan fuses offer tight current tolerance, low contact resistance, and stable performance across wide temperature ranges common in engine compartments. Their quick-acting characteristics reduce the risk of harness damage while still withstanding normal inrush current when the fan starts. When selecting a fuse, engineers evaluate fan motor rated current, start-up surge, system voltage, ambient temperature, and expected load duration. Proper coordination with relays, wiring gauge, and control modules ensures that the fuse opens only under abnormal conditions, supporting long service life and consistent cooling performance.

Impact on System Reliability and Maintenance

A correctly specified electric fan fuse increases overall reliability of the engine cooling system by isolating faults before they cascade into costly failures. It protects fan motors, wiring looms, and power distribution centers, reducing downtime and warranty claims. Routine inspection of fuse condition and replacement using parts that match original specifications help maintain stable operating temperatures and prevent engine overheating events. Diagnostic workflows often include verifying fuse continuity, checking for corrosion at fuse terminals, and confirming current draw of the fan circuit to ensure the protection scheme operates as designed.

1. What happens if the electric fan fuse keeps blowing?

A repeatedly blown fuse usually indicates a shorted fan motor, damaged wiring insulation, or incorrect fuse rating. Technicians should measure current, inspect connectors, and repair the underlying fault before installing a new fuse.

2. How is the correct fuse rating chosen for a cooling fan circuit?

The rating is based on the fan motor’s nominal current, start-up surge, system voltage, and wiring capacity. Manufacturers typically specify the proper amperage to ensure protection without nuisance tripping.

3. Can a higher-amp fuse be used to prevent nuisance failures?

Using a higher-amp fuse than specified is not recommended, as it can allow excessive current that overheats wiring and components. The correct solution is to address the cause of overload rather than increasing fuse capacity.