Engine Control Module Fuse Shields Automotive ECM Systems From Electrical Overloads

News 2025-11-17

The engine control module fuse plays a decisive role in protecting modern automotive powertrains from electrical damage. As vehicles integrate higher levels of electronics, from turbocharged gasoline engines to advanced diesel platforms and start‑stop systems, the ECM becomes the brain of the powertrain. The dedicated fuse that feeds this unit acts as a sacrificial barrier, interrupting abnormal current before it can corrupt control logic, damage processors, or cause wiring harness failures. Correct specification and placement of this fuse directly influence long‑term engine reliability, diagnostic accuracy, and vehicle uptime.

Core Function of the ECM Fuse in Vehicle Electronics

The primary function of the engine control module fuse is to isolate the ECM from overcurrent events caused by short circuits, wiring faults, or component malfunction. Positioned in the power distribution box, the fuse is calibrated to match the ECM’s typical load profile, including current spikes during ignition key‑on and sensor wake‑up. When current exceeds a defined threshold, the fuse element melts, breaking the circuit within milliseconds and preventing overheating of PCB tracks, power drivers, and memory devices. This controlled disconnection protects not only the ECU but also preserves critical calibration data and reduces the risk of thermal events in confined engine bays.

Key Performance Advantages and Design Characteristics

Modern ECM fuses are engineered to maintain stable resistance, tight current tolerance, and predictable time‑current behavior over a wide temperature range. Automotive‑grade blade or mini‑blade fuses are typically rated between 5 A and 30 A, supporting cold‑crank conditions and transient load spikes from actuators and relays. Low internal resistance helps minimize voltage drop at the ECM supply pin, supporting accurate sensor readings and stable injector and ignition control. High vibration resistance, moisture‑proof housings, and compliance with ISO and SAE standards enable consistent operation in under‑hood environments exposed to heat, oil mist, and mechanical shock.

Application Scenarios in Modern Powertrain and E‑Mobility Platforms

The ECM fuse is used across a wide range of platforms, including passenger cars, light commercial trucks, construction machinery, agricultural equipment, and marine engines. In turbocharged gasoline engines, the fuse safeguards the ECU’s high‑current drivers that manage direct injectors, ignition coils, and boost control valves. In heavy‑duty diesel applications, it protects complex control strategies for high‑pressure common‑rail systems and exhaust aftertreatment. Hybrid and plug‑in vehicles rely on dedicated fuses to secure both engine control units and auxiliary control modules interacting with inverters and battery management systems, ensuring safe interaction between low‑voltage control electronics and high‑voltage traction circuits.

Selection, Diagnostics, and Maintenance Considerations

Selecting the correct ECM fuse requires coordination between electrical engineers, ECU suppliers, and service documentation teams. Fuse rating, blow characteristics, and material must align with harness gauge, ECM peak current, and anticipated fault conditions. Underrated fuses can cause nuisance opens and intermittent no‑start complaints, while overrated parts may fail to clear faults quickly enough to prevent ECU damage. During diagnostics, a blown ECM fuse often appears as a no‑communication or no‑start condition. Technicians should always identify root causes such as shorted injectors, chafed harnesses, or water intrusion before replacing the fuse, preventing repeated failures and avoiding unnecessary ECU replacement.

1. Why does an ECM fuse blow repeatedly?

Repeated ECM fuse failures typically indicate underlying faults such as shorted actuators, damaged wiring insulation, corroded connectors, or internal ECU failures. The system should be inspected with a wiring diagram, current probe, and insulation tests before installing a new fuse.

2. Can a higher‑amp fuse be used on the ECM circuit?

Using a higher‑amp fuse on the ECM circuit is not recommended because it can delay circuit interruption, expose the control unit and harness to excessive current, and increase the risk of permanent ECU damage or overheating.

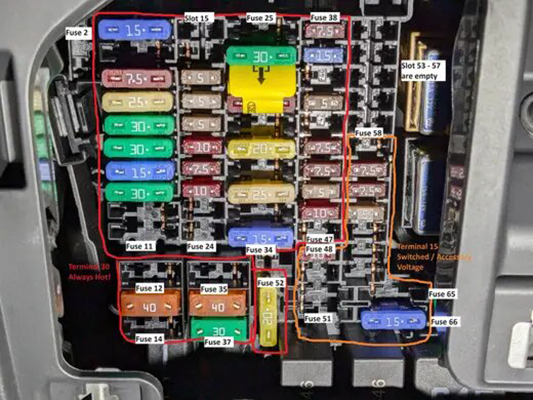

3. Where is the ECM fuse usually located in a vehicle?

The ECM fuse is commonly located in the main under‑hood fuse and relay box, often labeled as ECM, ECU, or EFI. The exact position and rating are listed in the vehicle’s service manual and on the fuse box cover diagram.