Enhancing reverse light protection through dedicated fuse solutions in vehicles

News 2025-11-17

Reverse light fuse protects reverse light system electrical connections by isolating sensitive wiring and components from abnormal current surges. In modern vehicles, the reverse light circuit is tightly integrated with electronic control units, parking sensors, and driver‑assistance cameras. A correctly specified fuse prevents thermal damage, connector degradation, and signal disruption when short circuits or wiring faults occur, maintaining safety and regulatory compliance while preserving downstream electronics.

Role of the reverse light fuse in automotive circuits

The reverse light fuse acts as a sacrificial element that opens the circuit when current exceeds its rated value. This function protects the switch or transmission range sensor, rear harness, connectors, and the reverse lamps themselves from overload conditions. In many late‑model cars, the same circuit also powers camera modules and proximity radar, so a well‑matched fuse rating stabilizes voltage delivery during frequent shifting between drive and reverse. By limiting fault propagation, the fuse helps maintain clean electrical environments that support accurate signaling to the body control module and preserve compliance with international lighting standards.

Application scenarios and integration in modern vehicles

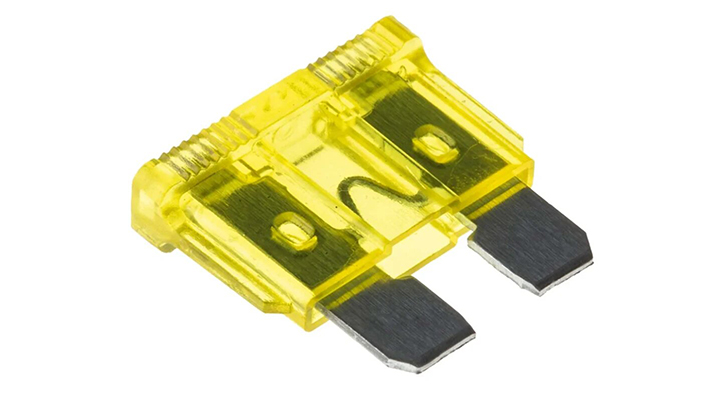

The reverse light fuse is used in passenger cars, commercial vans, trucks, trailers, and agricultural machinery where frequent low‑speed maneuvering is required. Typical scenarios include urban parking, loading docks, tight construction sites, and low‑visibility yards at night. Integration options range from standard blade fuses in interior or engine‑bay fuse boxes to mini and micro designs for compact platforms. Some manufacturers place a dedicated reverse light fuse on trailer power distribution modules to separate trailer faults from the towing vehicle. In electric vehicles, the fuse protects DC‑DC converter outputs feeding LED reverse lights and camera systems, preventing abrupt voltage drops that could corrupt digital video streams.

Performance advantages and selection considerations

High‑quality reverse light fuses offer precise current ratings, fast response to short circuits, and low contact resistance, which minimizes voltage loss to LED lamps and imaging electronics. Time‑current characteristics can be chosen to tolerate brief inrush currents while still interrupting sustained overloads, supporting both halogen bulbs and solid‑state lighting. Robust construction using corrosion‑resistant terminals and high‑temperature housings extends service life under engine‑bay heat, vibration, and moisture. When engineers select a fuse, they evaluate nominal circuit load, peak starting current, wiring gauge, ambient temperature, and applicable automotive standards such as ISO and SAE requirements to ensure stable long‑term performance.

Protection of connectors and wiring harness integrity

A properly coordinated reverse light fuse prevents overheated conductors, melted insulation, and damaged connectors in fault conditions caused by chafed wires, water ingress, or incorrect aftermarket modifications. By interrupting current before temperatures rise to harmful levels, the fuse preserves harness flexibility and connector contact pressure, reducing long‑term resistance growth and signal noise. This protection is crucial when reverse light wiring runs alongside sensor lines or communication buses, where thermal stress could introduce intermittent faults. Stable harness integrity supports accurate reverse detection, consistent lamp brightness, and dependable operation of rear safety systems over the vehicle lifetime.

1. What happens when the reverse light fuse blows

The reverse lights, and in many vehicles the rear camera and parking sensors, stop operating. The driver typically sees a warning on the instrument cluster or notices that the lights do not illuminate in reverse. The fuse must be inspected, the underlying fault repaired, and a replacement fuse of the correct rating installed.

2. How to choose the correct reverse light fuse rating

The fuse rating should exceed normal operating current but remain low enough to open quickly during faults. Engineers calculate expected load from lamps and electronics, add reasonable margin for inrush and temperature effects, and select a fuse that meets automotive standards and the vehicle manufacturer’s specifications.

3. Can upgrading lamps to LED affect the reverse light fuse

Yes. LED retrofits usually reduce steady‑state current but may change inrush behavior and interact differently with control modules. It is important to keep the original fuse rating unless the vehicle manufacturer or a qualified engineer specifies an alternative based on detailed circuit analysis.