Expert Advice on Fuse Installation to Prevent Loose Connections and Electrical Risks

News 2025-10-24

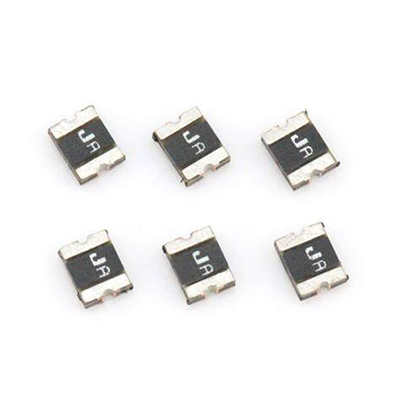

Fuses play a vital role in safeguarding electrical systems by interrupting circuits during overcurrent events, but loose connections can lead to serious dangers like arcing, overheating, and fires. In everyday scenarios such as automotive wiring, industrial machinery, and household appliances, improper installation is a common issue that compromises safety. This piece outlines practical approaches to ensure secure fuse setups, emphasizing performance benefits like enhanced reliability and reduced downtime in high-demand environments. By focusing on proper techniques, users can maintain optimal circuit protection and extend the lifespan of their systems.

Selecting the Correct Fuse for Your Application

Fuses vary by type and specification, making selection crucial for avoiding loose connections. For automotive use, blade fuses offer quick installation and resistance to vibration, while ceramic fuses suit industrial settings with their high-temperature tolerance and ability to handle larger currents. Matching fuse ratings to circuit demands—such as voltage and amperage—prevents mechanical stress that could loosen connections over time. This targeted approach not only boosts performance by ensuring fast fault response but also minimizes energy loss, promoting efficiency in applications like electric vehicles and manufacturing equipment.

Best Practices for Fuse Installation

Installing fuses correctly involves several key steps to eliminate risks of looseness. Begin by cleaning fuse holders to remove any oxidation or debris that might hinder a secure fit. Use calibrated tools to achieve the right torque, avoiding damage from over-tightening while ensuring firmness. In environments with constant movement, such as engines or conveyor systems, incorporate anti-vibration measures like locking nuts. These methods enhance connection integrity, leading to better electrical conductivity and reduced heat buildup, which in turn supports longer operational life and fewer interruptions in critical systems.

Essential Maintenance and Inspection Routines

Regular upkeep is essential to catch and correct loose connections before they escalate into hazards. Schedule periodic checks using visual inspections and tools like multimeters to verify continuity and tightness. Address signs of wear, such as corrosion or discoloration, promptly by replacing components. For systems in harsh conditions, adopt protective coatings or enclosures to shield fuses from environmental factors. This proactive strategy improves system reliability by sustaining performance advantages, such as quicker response to faults and lower maintenance costs, particularly in sectors like renewable energy and consumer electronics. Finally, here are three common questions and answers related to fuse installation:

1. What causes loose fuse connections?

Loose connections typically arise from insufficient tightening, exposure to vibrations, or material degradation over time, all of which can be mitigated with proper installation techniques.

2. How often should fuses be inspected?

Fuses should be inspected every six months or after significant events like repairs, to ensure connections remain secure and functional in various applications.

3. Can loose connections lead to specific hazards?

Yes, they can cause arcing and overheating, potentially resulting in electrical fires or equipment failure, underscoring the need for vigilant maintenance.