Fast-Acting-Type Fuse Technology Safeguarding High-Value Sensitive Electronic Components

News 2025-11-17

Fast-acting-type fuse rapid cutoff shields sensitive electronic components

Circuit Protection Demands in Modern Electronics

Fast-acting-type fuses answer the growing need to protect highly integrated ICs, precision analog stages, and miniature power modules from destructive overcurrent events. As supply voltages fall and current densities rise, even millisecond-scale overloads can punch through gate oxides, upset calibration data, or trigger latch-up in advanced semiconductors. Traditional time-delay devices often respond too slowly to transient faults such as short circuits in low-impedance DC rails, hot-plug events, or regulator failures. Fast-acting fuses provide a tightly controlled, low-I²t interruption that disconnects the fault path quickly enough to keep junction temperatures and energy dissipation within the safe operating limits of sensitive components.

Key Performance Characteristics and Cutoff Behavior

A fast-acting-type fuse is engineered to operate very close to its rated current, breaking the circuit in a narrowly defined time window when overload thresholds are exceeded. Critical performance metrics include rated voltage, breaking capacity, resistance, melting I²t, and typical pre-arcing time. The lower the I²t value, the less thermal stress is transferred to downstream semiconductors, which is vital in precision ADCs, RF front ends, and high-speed logic. Consistent, repeatable cutoff behavior across temperature and production lots helps designers predict protection margins during worst-case power-up, inrush current, and fault conditions. Low internal resistance minimizes voltage drop and power loss, preserving regulation accuracy in low-voltage rails such as 1.2 V or 1.8 V core supplies.

Application Scenarios Across Diverse Electronic Systems

Fast-acting-type fuses are widely deployed in application domains where downtime or component damage translates directly into service costs and quality issues. In industrial control systems, they protect PLC I/O cards, sensor loops, and communication modules from wiring shorts and misconnections in harsh field environments. In telecom and networking equipment, surface-mount fast-acting fuses guard DC-DC converter inputs, PoE interfaces, and line driver circuits, enabling compact board layouts while meeting safety and surge requirements. Consumer electronics, including gaming consoles, SSD-based storage devices, and wearable medical monitors, use these fuses to shield tiny BGA-packaged ICs from charger faults, battery pack anomalies, and USB overcurrent conditions, reducing warranty returns and unexpected field failures.

Selection, Integration, and Design Best Practices

Correct selection of a fast-acting-type fuse starts with analyzing normal operating current, peak inrush, ambient temperature, and fault-clearing requirements of the target circuit. Engineers typically choose a rated current 25–50% above steady-state load, then confirm that inrush profiles do not cause nuisance openings by reviewing time-current curves. Coordination with upstream protection such as PTC resettable devices, transient voltage suppressors, or circuit breakers ensures that the fuse opens first in local board-level faults. PCB layout should minimize trace inductance and ensure robust solder pads to withstand fault energy and mechanical stress. Compliance with standards such as IEC 60127 or UL 248 helps guarantee consistent performance under international safety regimes and eases certification.

Performance Advantages and Impact on System Reliability

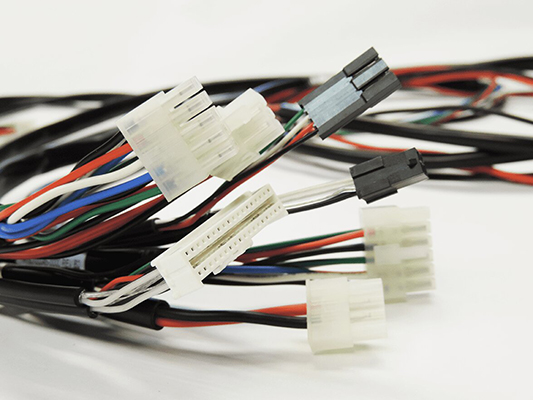

Compared with general-purpose or slow-blow fuses, fast-acting-type devices deliver tighter control over fault energy and enable more precise protection of high-value silicon. Their rapid interruption limits secondary damage, preventing overheating of connectors, cable harnesses, and PCB substrates. This directly improves mean time between failures and maintains electrical stability in mission-critical systems such as medical diagnostic equipment, industrial robots, test instruments, and automotive infotainment modules. From an SEO perspective, phrases like “fast-acting fuse circuit protection,” “rapid cutoff overcurrent safety,” and “sensitive electronic component shielding” reflect exactly what design engineers seek when optimizing reliability in compact, high-density electronics.

1, How does a fast-acting fuse protect sensitive ICs?

It interrupts overcurrent in a very short time, keeping fault energy and junction temperature low enough to prevent damage to delicate semiconductor structures.

2, Where are fast-acting fuses most commonly used?

They are widely used in industrial control units, telecom boards, consumer electronics, medical devices, and any application that contains high-value or precision electronic components.

3, What factors matter most when choosing a fast-acting fuse?

Key factors include steady-state load current, inrush profile, rated voltage, breaking capacity, melting I²t, ambient temperature, and compliance with relevant safety standards.