Robust Wire Harness Structures for Automotive Engine Bay Electrical Connections

News 2025-10-31

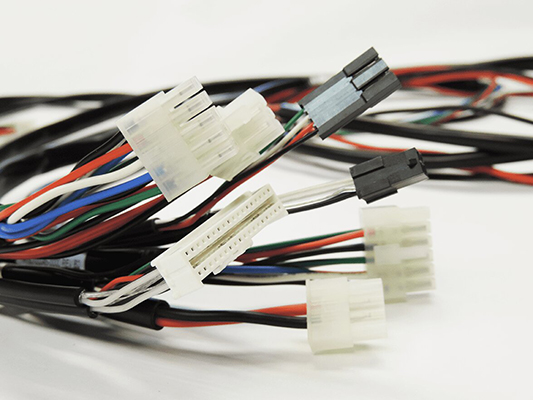

Wire harnesses are essential components in automotive systems, particularly in the engine bay, where they manage complex electrical connections. These assemblies bundle wires and cables to ensure reliable signal and power transmission amidst challenging conditions like high temperatures, vibrations, and exposure to fluids. In modern vehicles, robust wire harness structures enhance safety and efficiency by minimizing electrical failures, which can lead to costly downtime or accidents. As automotive technology advances, the demand for durable harnesses grows, with engineers focusing on materials and designs that withstand the rigors of engine environments.

Key Design Elements

In crafting wire harnesses for engine bays, engineers prioritize materials such as cross-linked polyethylene or silicone insulation that resist heat and chemicals. Connectors and terminals often feature corrosion-resistant coatings and secure locking mechanisms to handle vibrations without loosening. Modular designs allow for easier assembly and maintenance, reducing weight while maintaining structural integrity. These elements ensure that harnesses fit precisely within the confined spaces of the engine compartment, optimizing space and improving overall vehicle aerodynamics and fuel efficiency.

Performance and Application Benefits

Robust wire harness structures offer significant advantages in automotive applications, including enhanced durability that extends component life and reduces replacement needs. They provide superior electrical performance by minimizing signal interference and voltage drops, crucial for sensors and control units in the engine bay. In real-world scenarios, such as heavy-duty trucks or electric vehicles, these harnesses maintain functionality under extreme conditions, leading to better reliability and lower maintenance costs. Their design also supports integration with advanced systems like ADAS, ensuring seamless operation in dynamic driving environments.

Frequently Asked Questions

1. What defines a robust wire harness?

A robust wire harness uses high-quality materials and engineering to endure harsh conditions, ensuring long-term reliability in automotive settings.

2. How do these structures improve engine bay safety?

They reduce the risk of short circuits and failures by incorporating vibration resistance and thermal protection, enhancing overall vehicle safety.

3. What maintenance is required for such harnesses?

Regular inspections for wear and secure connections are key, with replacements needed only after extensive use, minimizing downtime.