Fuse Box Technologies for Enhanced Safety in Construction Vehicles and Heavy Machinery

News 2025-10-20

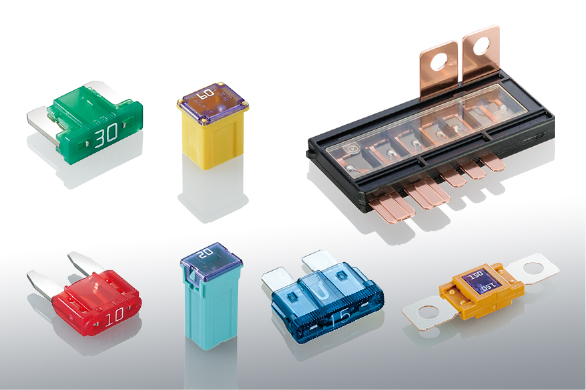

In the rigorous environments of construction and heavy machinery operations, fuse boxes serve as vital components for electrical protection. They are engineered to detect and interrupt excessive current, thereby preventing damage to critical systems and reducing the risk of fires or equipment failure. This protection is essential in industries where machinery operates under high stress, ensuring that vehicles like excavators and bulldozers maintain functionality and safety standards. By integrating advanced fuse technologies, operators can achieve greater reliability, minimizing unexpected breakdowns that could lead to project delays or safety incidents.

Application Scenarios

Fuse boxes are deployed in various construction vehicles and heavy machinery to safeguard specific electrical circuits. For example, in excavators, they protect hydraulic and control systems from overloads, while in dump trucks, they ensure the integrity of lighting and braking systems during intense operations. These components are also crucial in cranes and loaders, where they handle the demands of repetitive motions and heavy loads. In challenging settings such as mining or road construction, fuse boxes are designed to endure extreme temperatures, vibrations, and contaminants, providing consistent performance that supports uninterrupted workflow and enhances overall site efficiency.

Performance Advantages

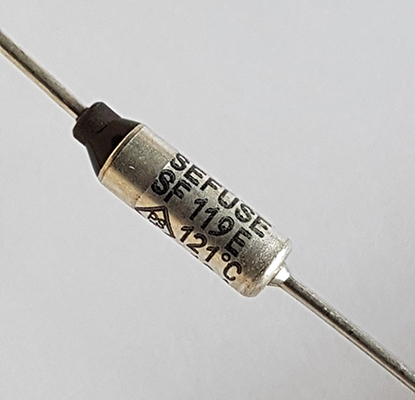

Key strengths of fuse boxes in this sector include their high durability and rapid fault response, which are critical for maintaining operational continuity. Constructed from robust materials like reinforced plastics or metals, they resist corrosion and impact, extending service life in harsh conditions. Additionally, features such as precise current ratings and thermal protection help optimize energy use and prevent overheating, contributing to better fuel efficiency and reduced maintenance costs. This reliability not only boosts machinery uptime but also supports compliance with safety regulations, making fuse boxes a smart investment for long-term performance in construction applications.

Frequently Asked Questions

1、What factors influence the choice of fuse box for heavy machinery?

Answer: Key factors include the machinery’s voltage requirements, environmental exposure, and specific current needs to ensure compatibility and optimal protection.

2、How do fuse boxes improve safety in construction vehicles?

Answer: They quickly disconnect circuits during faults, preventing electrical fires and protecting operators from hazards in dynamic work environments.

3、Can fuse boxes be integrated into existing heavy equipment?

Answer: Yes, many designs allow for easy retrofitting, enabling upgrades that enhance safety and efficiency without major modifications.