Glass Fuses: Essential Protection for Truck Lighting Circuits

News 2025-10-27

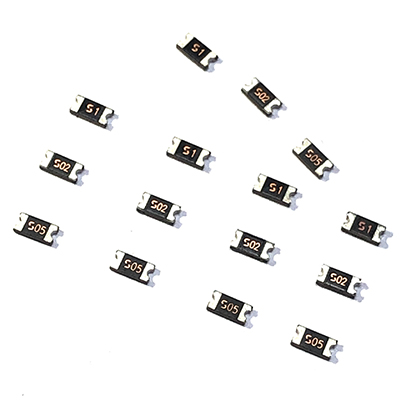

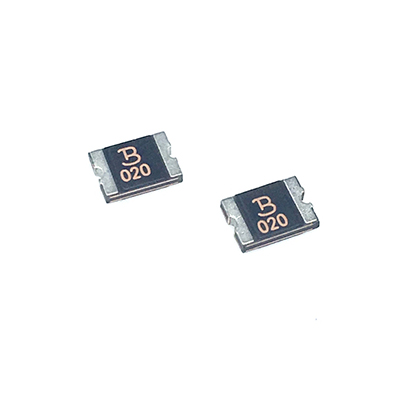

Glass fuses play a crucial role in safeguarding truck lighting circuits by providing reliable overcurrent protection. These devices are designed to break electrical circuits when excessive current flows, preventing damage to wiring and components in heavy-duty vehicles. In the context of truck lighting, which includes headlights, taillights, and signal indicators, glass fuses ensure safe operation under various driving conditions. Their compact size and ease of integration make them a standard choice in automotive electrical systems, enhancing overall vehicle reliability and safety.

Application Scenarios

Glass fuses are widely used in truck lighting circuits for specific applications that demand quick and effective fault protection. For instance, in headlight systems, they guard against surges caused by voltage spikes or wiring issues, maintaining visibility during night driving. Similarly, in taillight and brake light circuits, these fuses prevent short circuits that could arise from environmental factors like moisture or vibration. Their application extends to auxiliary lighting, such as fog lights or emergency beacons, where consistent performance is vital for road safety. By integrating glass fuses, truck manufacturers and maintenance teams can ensure that lighting systems remain functional and compliant with industry standards.

Performance Advantages

One key benefit of glass fuses in truck lighting is their transparency, allowing for easy visual inspection to check if the fuse has blown, which simplifies troubleshooting. They offer fast response times to overcurrent events, minimizing potential damage to sensitive lighting components. Additionally, glass fuses are cost-effective and durable, withstanding the harsh conditions typical in trucking, such as temperature extremes and mechanical stress. Their standardized sizes and ratings make them interchangeable, facilitating repairs and upgrades. Overall, these attributes contribute to improved system longevity and reduced downtime for fleet operations.

Frequently Asked Questions

1. What are common ratings for glass fuses in truck lighting?

Common ratings range from 5 to 20 amps, depending on the circuit load, with 10 amps often used for standard lighting applications to handle typical current draws safely.

2. How do you identify a blown glass fuse?

A blown glass fuse can be identified by a broken filament inside the glass tube or discoloration; use a multimeter for confirmation by checking continuity.

3. What materials are glass fuses made from?

Glass fuses typically feature a glass tube with metal end caps and a thin wire filament, designed to melt and break the circuit when overcurrent occurs.