Heat-Proof Thermal Fuse Ensures Safety in High-Temperature Automotive Environments

News 2025-11-27

Heat-proof thermal fuses are now a key safeguard in modern vehicles, where power electronics, compact packaging, and turbocharged engines raise ambient temperatures. In engine compartments, battery management units, seat heaters, and on-board chargers, components are often exposed to continuous heat, thermal spikes, and poor airflow. A properly selected thermal fuse interrupts current once a critical temperature is reached, preventing meltdown of plastic housings, connector damage, and in extreme cases, vehicle fires. This simple one-time protection element helps OEMs meet stringent automotive safety and regulatory standards while maintaining high power density.

Robust Design for Hot Vehicle Zones

Heat-proof thermal fuses used in harsh automotive locations are engineered to maintain accurate opening characteristics even when mounted near exhaust manifolds or power MOSFETs. The fusible alloy, organic pellet, and spring mechanism are stabilized across long-term exposure to elevated ambient temperatures, humidity, and vibration. Low contact resistance minimizes self-heating, keeping the cut-off point precise. Typical opening temperatures are tuned between 115 °C and 240 °C, matching the thermal limits of coils, windings, or polymer housings. Compliance with AEC-Q200 and UL standards ensures consistent behavior across millions of cycles, a key consideration for global vehicle platforms.

Key Performance Advantages and Safety Benefits

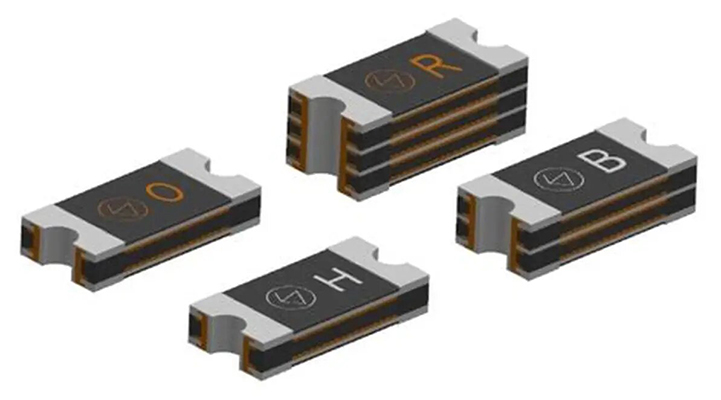

A major advantage of these thermal fuses is fast and predictable operation under fault conditions. When cooling fans fail or charging modules experience runaway, the fuse responds directly to temperature rather than current, breaking the circuit before insulation or potting material reaches degradation. The compact axial or radial package integrates easily into wiring harnesses and PCB assemblies. Low leakage, high dielectric strength, and stable performance over the full automotive temperature range support high-voltage battery packs as well as low-voltage accessory systems. By eliminating resettable behavior, the device prevents repeated stress on damaged components, supporting functional safety concepts based on permanent fault isolation.

Core Automotive Application Scenarios

In engine control and under-hood fuse boxes, heat-proof thermal fuses protect blower motors, ABS pumps, and transmission solenoids from blocked rotors or seized bearings. EV and hybrid platforms use them inside battery junction boxes, DC/DC converters, and on-board chargers to stop overheating due to overcurrent or cooling system faults. Seat heaters, steering wheel heaters, and HVAC actuators benefit from direct thermal sensing near resistive elements, avoiding scorching of foam or trim materials. Their high-temperature endurance enables placement right next to coils and power stages rather than far away on cooler parts of the harness, reducing response time and wiring complexity.

Integration, Selection, and SEO-Relevant Considerations

When selecting a heat-proof thermal fuse, engineers match holding temperature and opening temperature to the maximum safe limit of the protected component, then apply adequate derating based on ambient conditions and expected lifetime. Proper thermal coupling using clips, epoxy, or direct contact surfaces ensures that the fuse senses the actual hotspot rather than the surrounding air. In automotive electronics design, keywords such as thermal protection, overheating prevention, safety fuse, and high-temperature automotive component indicate the critical role of this device in protecting wiring, PCBs, and power modules. Early placement in the design phase simplifies compliance testing, shortens validation time, and supports long-term field reliability.

1、Typical opening temperature range

Heat-proof thermal fuses for automotive use usually open between about 115 °C and 240 °C, selected according to the thermal rating of coils, plastics, or insulation materials.

2、Difference between thermal fuse and standard fuse

A thermal fuse responds to temperature and opens once when overheating occurs, while a standard fuse reacts mainly to excessive current and may not protect against gradual thermal buildup.

3、Main automotive locations using heat-proof thermal fuses

They are commonly installed in engine compartments, electric heater circuits, battery packs, DC/DC converters, and on-board chargers to prevent overheating of critical components.