Side Marker Light Fuse Protects Vehicle Visibility And Lighting Integrity

News 2025-11-17

Side marker light fuse protects side marker illumination systems by isolating faults and maintaining safe operation of exterior lighting. In modern automotive and commercial vehicles, these small fuses are key components of the low‑voltage power distribution network, guarding LED or incandescent marker lamps from overcurrent, wiring shorts, and moisture‑induced failures. Correctly specified fuses support regulatory compliance, stable night‑time visibility, and long service life of lamps located on trailers, trucks, buses, and special‑purpose equipment.

Functional Role In Vehicle Lighting Circuits

Side marker light fuses sit between the battery supply or body control module and the marker lamp harness. When current exceeds the rated value due to a pinched cable, connector corrosion, or internal lamp defect, the fuse opens rapidly, preventing overheating of plastic housings, melted insulation, or damage to multiplex lighting controllers. In modern CAN‑based architectures, marker circuits may be grouped, so dedicated fuses for left, right, or trailer outputs help isolate failures, simplify troubleshooting, and avoid blacking out the entire exterior lighting system.

Key Performance Features And Protection Advantages

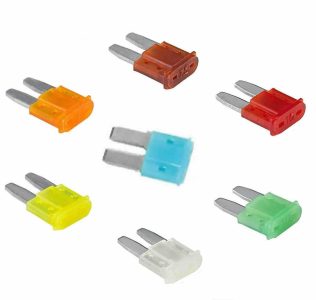

From an engineering perspective, the most important characteristics are rated current, voltage withstand, interruption capacity, and time‑current curve. Correct matching to the inrush profile of LED drivers or filament bulbs prevents nuisance blowing while still reacting fast enough to short circuits. High rupture capacity avoids case rupture under severe fault energy. Automotive blade fuses, mini and micro variants, offer low contact resistance and stable behavior under vibration and temperature swings from –40 °C to +125 °C. These performance advantages increase marker lamp uptime, reduce warranty claims, and protect adjacent circuitry in body control modules.

Application Scenarios In Passenger, Commercial, And Off‑Highway Fleets

Side marker light fuses are widely used in passenger cars, light trucks, heavy‑duty tractors, trailers, buses, and construction machinery where legal side illumination is mandatory. Fleet operators benefit from clearly labeled fuse boxes that separate side markers from brake, turn, and headlamp functions, enabling quick roadside service. In trailer applications, dedicated fuses protect long harness runs exposed to road salt and mechanical stress. Agricultural and mining vehicles use higher‑rated fuses to cope with frequent cycling, auxiliary marker bars, and harsh environmental conditions that increase the risk of intermittent shorts.

Selection, Installation, And Maintenance Considerations

Correct fuse selection starts by calculating steady‑state lamp current, including LED driver overhead or filament surge. Engineers then apply suitable derating based on ambient temperature and expected duty cycle. Use only components that meet automotive standards such as ISO, SAE, and AEC‑Q compliance where required. During installation, ensure tight fuse‑to‑socket contact, proper orientation, and environmental sealing in engine bay or under‑chassis locations. Maintenance teams should use a test lamp or multimeter instead of oversizing the fuse when repeated blowing occurs, since installing a higher rating can mask wiring faults and compromise fire safety.

Frequently Asked Questions

1. What symptoms indicate a blown side marker light fuse?

Typical signs include all side marker lights on one side or one vehicle segment going dark while turn signals and brake lamps still function. The issue is often confirmed when the fuse appears open on inspection or measures open‑circuit with a multimeter.

2. Can a larger‑rated fuse be used to stop frequent failures?

Using a higher‑rated fuse is not recommended, as it may allow wiring or connectors to overheat during a fault. Frequent fuse opening usually points to damaged insulation, water ingress, or a defective lamp module that should be identified and repaired.

3. How often should side marker light fuses be replaced as preventive maintenance?

Under normal conditions, fuses are not wear items and do not require scheduled replacement. They should only be replaced after a fault is diagnosed and corrected, or when upgrading the lighting circuit in line with documented design calculations.