High-Performance Durable Wire Harness Constructions Enhancing Reliability in Automotive Door Lock Mechanisms and Security Electrical Systems

News 2025-10-31

Wire harnesses are critical components in modern automotive systems, particularly in door lock and security setups. These structures ensure the efficient transmission of electrical signals and power, supporting features like keyless entry, anti-theft mechanisms, and automated locking. In the automotive industry, robust wire harness designs are essential for maintaining system integrity under harsh conditions such as vibrations, temperature extremes, and exposure to moisture. By focusing on sturdy materials and precise engineering, manufacturers can enhance the overall safety and functionality of vehicles, reducing the risk of electrical failures that could compromise security.

Application Scenarios in Automotive Security

Wire harnesses play a pivotal role in various application scenarios within automotive door lock and security systems. For instance, in electric vehicles, they connect sensors for proximity detection and biometric access controls, enabling seamless integration with central locking mechanisms. In traditional combustion engine cars, these harnesses facilitate connections between door modules and the vehicle’s central computer, supporting features like remote start and alarm systems. Additionally, in high-end models, wire harnesses are used in advanced driver-assistance systems (ADAS) that incorporate door lock functions with collision avoidance, ensuring reliable performance in dynamic driving environments and enhancing user safety.

Key Performance Advantages

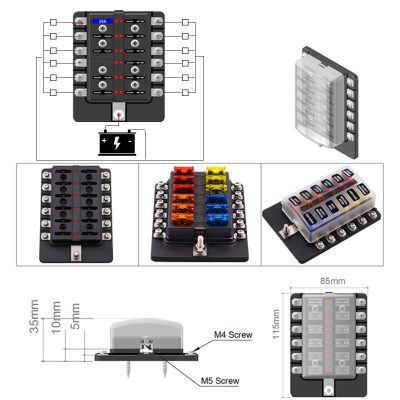

The performance advantages of sturdy wire harness structures are evident in their ability to withstand mechanical stress and environmental factors. Constructed from high-grade materials like reinforced insulation and corrosion-resistant connectors, these harnesses offer superior durability, extending the lifespan of automotive security components. They provide excellent electrical conductivity and minimal signal loss, which is crucial for precise operation of door lock actuators and security sensors. Moreover, their compact and organized design reduces weight and space requirements, improving fuel efficiency in conventional vehicles and energy management in electric ones, while maintaining high reliability to prevent system downtimes.

Common Questions

1. What materials are typically used in automotive wire harnesses for security systems?

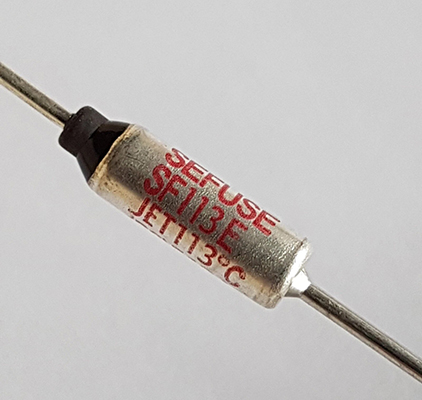

They often include copper wiring for conductivity, thermoplastic insulation for flexibility, and sealed connectors to protect against moisture and debris.

2. How do wire harnesses contribute to energy efficiency in vehicle security features?

By minimizing electrical resistance and optimizing signal paths, they reduce power consumption in components like door lock motors and security alarms.

3. What testing standards ensure the reliability of wire harnesses in automotive applications?

Standards such as ISO 6722 and SAE J1127 are commonly used, involving tests for vibration resistance, temperature cycling, and electrical integrity to guarantee performance.