High-Precision-Response Thermal Fuse Meets Strict Vehicle Safety Requirements

News 2025-11-27

High-Precision-Response Thermal Fuse Meets Stringent Automotive Safety Regulations and Design Demands

Thermal Protection in Modern Vehicle Architectures

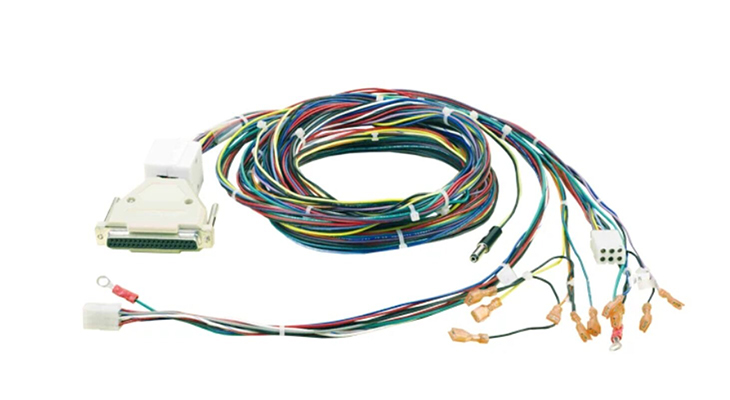

High-precision-response thermal fuses play a decisive role in protecting vehicle electrical and electronic systems as power densities rise and under‑hood temperatures fluctuate. In hybrid and battery electric platforms, compact battery junction boxes, DC‑DC converters, on‑board chargers, and motor control units depend on accurate, one‑time thermal cutoff to interrupt abnormal current paths triggered by overheating. A fuse that opens at a narrowly controlled temperature helps safeguard wire harnesses, connector blocks, and high-value modules from thermal runaway, insulation damage, and potential fire hazards. Compliance with ISO 26262 functional safety concepts and UN ECE R100 battery safety provisions increasingly pushes designers to select thermal fuses whose trip temperature, current rating, and interrupting capability are characterized under automotive operating profiles rather than generic consumer conditions.

Key Performance Advantages and Technical Features

The core advantage of a high-precision-response thermal fuse is its tightly specified opening temperature, often controlled within a narrow tolerance band to ensure consistent behavior across production lots. The fusible alloy and internal structure are engineered to react rapidly to defined temperature thresholds while avoiding nuisance openings at short thermal transients. High interrupting capacity enables the fuse to break fault currents present in 12 V, 24 V, and high-voltage EV bus systems without arcing or case rupture. Low internal resistance supports minimal power dissipation in normal operation, which is critical in compact modules where even small temperature rises affect long-term reliability. Compliance testing covers vibration, mechanical shock, humidity, thermal cycling, and long-duration overload, aligning device performance with harsh vehicle environments. These characteristics allow the fuse to maintain stable protection margins across the full automotive temperature range.

Automotive Application Scenarios and Integration Considerations

In powertrain domains, thermal fuses are integrated into inverter cooling plates, heater circuits, turbocharger actuators, and transmission control modules, where localized hotspots can develop despite system-level diagnostics. In xEV applications, they are embedded in battery cells or modules as part of multi-level safety concepts that combine current sensing, temperature monitoring, and passive cutoff elements. Infotainment head units, LED lighting drivers, and ADAS control units employ compact, board-mounted thermal fuses to prevent PCB charring in the event of regulator failures or blocked ventilation. For design engineers, key integration parameters include mounting orientation, creepage and clearance distances, and compatibility with reflow or wave soldering processes. Selecting a fuse certified to AEC‑Q200 or equivalent automotive qualification simplifies documentation during PPAP submission and accelerates the path to SOP.

Quality Compliance, Standards, and Lifecycle Reliability

To meet strict vehicle safety requirements, high-precision-response thermal fuses are produced under rigorous quality control aligned to IATF 16949 and ISO 9001 frameworks. Statistical process control, 100% functional screening of opening temperature, and traceable lot identification ensure consistency across large volumes. Reliability validation includes endurance under continuous rated current, surge current tests aligned to automotive load dump conditions, and verification of insulation resistance after fault activation. Many products achieve UL and TÜV recognition, which supports global homologation when combined with OEM-specific standards. Lifecycle considerations extend beyond initial activation: designers must assess aging behavior, potential drift in opening temperature after long-term exposure, and the effect of repeated thermal cycling on mechanical stability, particularly in under‑hood or battery pack environments.

FAQs on High-Precision Thermal Fuses in Vehicles

1What distinguishes a high-precision-response thermal fuse in automotive use

The defining trait is the narrow opening temperature tolerance combined with high interrupt ratings and proven performance under automotive stress tests, enabling predictable protection in critical modules such as battery systems and inverters.

2How should engineers select opening temperature and current rating

Selection should reflect the maximum normal operating temperature and current of the target circuit, leaving sufficient margin above typical conditions yet below the onset of insulation degradation or component damage identified through worst-case simulations.

3Are thermal fuses compatible with electronic monitoring systems

Yes, they complement electronic sensors and control algorithms by providing a passive, fail-safe layer that operates independently of software, supplying irreversible cutoff when control units or harnesses experience unexpected thermal events.