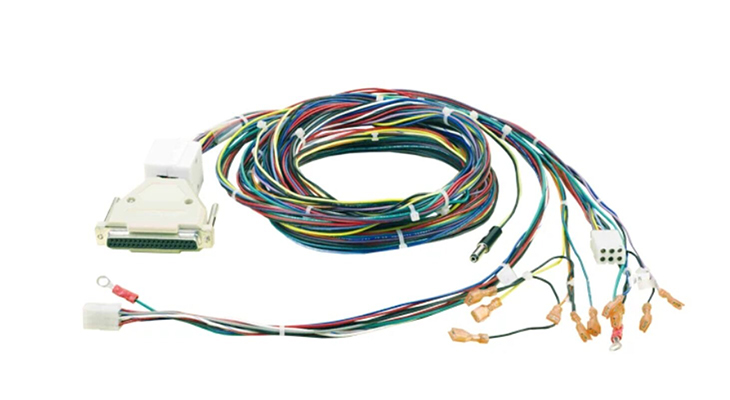

Key Techniques for Addressing Common Problems in Wire Harnesses Such as Fraying and Connector Loosening

News 2025-10-24

Wire harnesses are critical components in various electronic systems, ensuring reliable connections in applications ranging from automotive vehicles to industrial machinery. These assemblies can suffer from issues like wire fraying and connector loosening, which compromise performance and safety. Understanding effective repair methods is essential for maintaining system integrity and extending the lifespan of the harness. By focusing on targeted solutions, technicians can restore functionality and prevent future failures in diverse settings.

Repairing Wire Fraying

Wire fraying often occurs due to mechanical stress, abrasion, or environmental exposure in scenarios like automotive wiring or equipment in harsh conditions. To repair frayed wires, start by identifying the damaged section and stripping away the affected insulation carefully. Use heat-shrink tubing or insulating tape to reinforce the area, ensuring a secure and insulated repair. This approach not only restores electrical continuity but also enhances durability, reducing the risk of short circuits and improving overall system reliability in high-vibration environments.

Fixing Connector Loosening

Connector loosening is commonly caused by thermal cycling, vibration, or improper installation, prevalent in aerospace and consumer electronics. Effective fixes involve inspecting the connector for wear and applying thread-locking compounds or replacing with secure fasteners. Tightening to manufacturer specifications and using anti-vibration mounts can prevent recurrence. These methods boost connection stability, minimizing signal loss and enhancing performance under dynamic conditions, which is crucial for safety-critical applications.

Frequently Asked Questions

1. What causes wire fraying?

Wire fraying typically results from repeated bending, exposure to chemicals, or physical abrasion in daily use.

2. How can connector loosening be prevented?

Prevent loosening by using high-quality connectors with locking mechanisms and regular maintenance checks in vulnerable setups.

3. What tools are essential for these repairs?

Essential tools include wire strippers, crimping tools, heat-shrink tubing, and a multimeter for accurate diagnosis and repair.