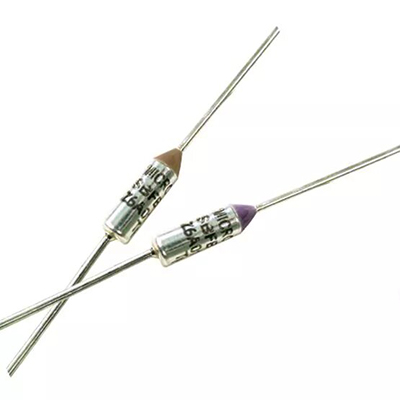

High-Temp-Tolerance Thermal Fuse Handles Extreme Heat in Vehicle Engines and Under-Hood Systems

News 2025-11-27

High-temp-tolerance thermal fuses are becoming a key safety component in modern vehicle engines, where compact layouts, turbocharging, and electrification push under‑hood temperatures to new extremes. These fuses provide a non-resettable, one-time disconnect that protects wiring harnesses, power electronics, and sensors from catastrophic overheating. By cutting off current precisely at a calibrated temperature, they help prevent smoke, fire, and permanent damage to cost-sensitive engine and drivetrain modules.

Engine and Under-Hood Application Scenarios

High-temperature thermal fuses are widely used in engine control units (ECU), starter–generator systems, electric water pumps, turbocharger actuators, and transmission control modules. In these zones, ambient temperatures can exceed 150°C, while localized hot spots rise even higher near exhaust manifolds and turbo housings. The fuse is typically mounted in series with the primary power line or within heater circuits such as intake air heaters, battery warmers, and diesel aftertreatment heaters. When abnormal thermal conditions occur—due to blocked airflow, stuck relays, bearing seizure, or PCB failure—the fuse responds by permanently opening the circuit, preventing thermal runaway in confined engine compartments.

Key Performance Advantages Under Extreme Heat

The standout feature of a high-temp-tolerance thermal fuse is its certified opening temperature, often ranging from 184°C up to 240°C or higher, paired with long-term stability under continuous high ambient stress. Automotive-grade designs offer low contact resistance to reduce I²R losses, high interrupting capability to manage inrush currents from motors and solenoids, and robust mechanical construction that withstands harsh vibration and thermal cycling. The fusible alloy and encapsulation materials are engineered to avoid nuisance openings, maintaining precise trip points even after thousands of engine heat‑soak cycles, cold starts, and rapid temperature swings.

Design Integration and Safety Compliance

When integrated into vehicle engines, thermal fuses must meet stringent standards such as AEC‑Q200, UL, and relevant ISO safety regulations. Designers position the fuse close to the most thermally stressed components, often on metal heatsinks or near power MOSFETs and IGBT modules in motor drives. Proper derating of current and temperature, along with careful routing to minimize voltage drop, ensures the fuse functions accurately under real driving conditions. Using these fuses also supports functional safety concepts in ISO 26262, as they provide a deterministic, hardware-based fail-safe layer that complements diagnostic software and current-sensing circuitry.

Impact on Engine Efficiency and System Longevity

By preventing thermal damage, high-temperature fuses indirectly extend the service life of wiring, connectors, and power semiconductors, which can degrade quickly when exposed to repeated overheating. Protecting auxiliary drives and pumps keeps coolant circulation and lubrication stable, supporting consistent engine efficiency and emissions control. The compact size and customizable lead configurations ease integration into existing engine platforms, which is especially important as automakers add more electrical loads for hybrid systems, start-stop functions, and advanced driver assistance units that share the under‑hood space.

FAQs on High-Temperature Thermal Fuses in Engines

1. Where are thermal fuses typically placed in vehicle engines?

They are commonly installed in ECUs, electric pumps, heater circuits, and near high-power components where localized hot spots can occur.

2. Can a high-temp thermal fuse be reset after activation?

No. It is a one-time protective device that must be replaced once it opens the circuit.

3. How does a thermal fuse differ from a standard automotive fuse?

A standard fuse reacts primarily to overcurrent, while a thermal fuse responds to excessive temperature, delivering protection when heat, not just current, becomes dangerous.