Horn Fuse Solutions That Keep Vehicle Acoustic Warning Circuits Safe And Stable

News 2025-11-17

Horn fuse ensures horn operates safely without circuit overloads in modern vehicles where electrical loads continue to increase. As more driver‑assistance modules and comfort electronics share the same supply rail, the horn circuit must be protected against short circuits, wiring faults, and excessive current surges. A correctly selected fuse prevents harness damage, protects the horn relay and switch contacts, and supports compliance with automotive safety standards.

Core Functions Of A Horn Fuse In The Vehicle Electrical System

The horn fuse sits between the battery supply and the horn relay or horn module, acting as a sacrificial link that opens when current exceeds a defined threshold. In normal operation, it introduces minimal resistance and voltage drop, so acoustic output remains strong and consistent. When a wiring short to ground, corroded connector, or seized horn motor causes overcurrent, the fuse element heats rapidly and breaks the circuit, stopping further damage. Correct coordination between the fuse rating, wire gauge, and horn current profile is vital, especially in high‑current dual‑tone horns and air horn compressors used in trucks and buses.

Application Scenarios From Passenger Cars To Heavy-Duty Platforms

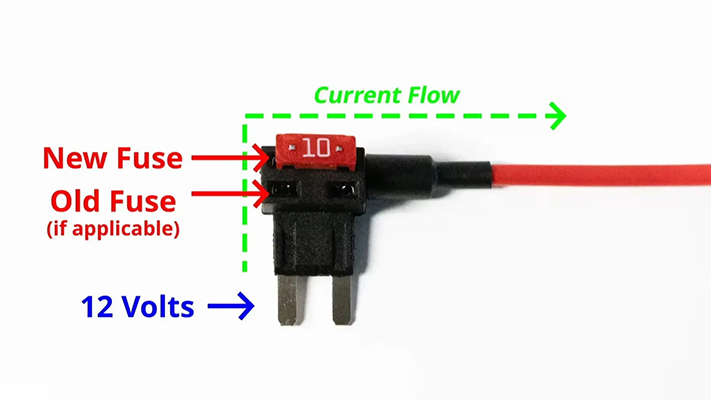

Horn fuses are deployed across compact cars, SUVs, commercial vans, heavy trucks, construction machinery, and agricultural vehicles. In dense urban traffic, passenger car horns are used frequently for short signals, demanding consistent performance during repeated activation. Heavy‑duty platforms rely on high‑power horns that draw significantly higher current, particularly under low‑temperature conditions, so the fuse must withstand brief inrush peaks without nuisance opening. OEMs often integrate blade fuses in centralized fuse boxes, while aftermarket horn upgrades may require inline waterproof fuse holders mounted close to the battery. Electric vehicles and hybrid platforms also depend on accurate horn fuse selection, as their DC architectures and high levels of onboard electronics raise the importance of fault discrimination and EMC robustness.

Performance Advantages Of Proper Fuse Selection And Design

Choosing the right horn fuse rating and construction improves safety, durability, and serviceability. Time‑delay blade fuses can tolerate the short inrush spike when the horn coil or compressor starts, yet still clear persistent overloads caused by insulation damage or mis‑wiring. Quality fuses maintain stable characteristics across temperature ranges typically from −40 °C to +125 °C, which is important in engine compartment fuse boxes exposed to vibration, moisture, and thermal cycling. Clear amperage markings, color‑coded housings, and standardized footprints simplify maintenance in workshops and reduce the risk of incorrect replacement. Low‑resistance fuse elements help preserve horn loudness, which is important for meeting acoustic regulations and ensuring the vehicle remains audible in noisy environments.

Selection Considerations And Maintenance Best Practices

Engineers and technicians should match the fuse rating to the horn’s continuous current draw plus an appropriate safety margin, while still coordinating with wire cross‑section and connector ratings. Using a higher‑amp fuse than specified can allow dangerous conductor overheating, whereas undersized fuses may blow during normal horn operation. During diagnostics, a repeatedly blown horn fuse usually indicates downstream problems such as chafed wires, water intrusion into the horn assembly, or a failing relay. For aftermarket retrofits, installing an inline fuse as close as possible to the power source shortens the unprotected wire length and improves overall system safety. Periodic visual inspection of fuse boxes, checking for discoloration, corrosion, or loose seating, helps maintain stable horn performance throughout the vehicle service life.

1、Why does the horn fuse blow frequently?

A horn fuse that opens repeatedly typically points to a shorted horn coil, damaged wiring insulation, or a stuck relay keeping the circuit energized; the root cause must be located and repaired before fitting a new fuse.

2、Can a higher-amp horn fuse be used during upgrades?

Using a higher‑amp fuse than specified is not recommended; instead, the horn circuit should be redesigned with appropriate wiring, relay capacity, and OEM‑level validation to handle increased current safely.

3、Where is the horn fuse usually located in a vehicle?

The horn fuse is usually found in the main engine‑bay or interior fuse box, identified on the fuse‑box cover or in the service manual, and in some aftermarket installations it may appear in an additional inline holder near the battery.