Tailoring Wire Harness Configurations to Enhance Electrical Systems in ATV and UTV Applications for Optimal Performance

News 2025-10-31

In the dynamic world of off-road vehicles, All-Terrain Vehicles (ATVs) and Utility Terrain Vehicles (UTVs) rely heavily on sophisticated electrical systems to navigate tough terrains and support various functionalities. Customized wire harness configurations are essential for integrating components like lighting, GPS, and power systems seamlessly. These tailored setups not only address the unique demands of recreational and professional use but also improve overall vehicle reliability and efficiency, making them a key consideration for manufacturers and users alike.

Diverse Application Scenarios

Wire harness configurations find extensive use in scenarios ranging from agricultural tasks to recreational adventures. In farming, ATVs and UTVs equipped with custom harnesses handle heavy-duty operations like towing and powering implements, ensuring consistent electrical flow despite dust and moisture. For outdoor enthusiasts, these setups support advanced features such as winches and audio systems during off-road excursions, enhancing user experience by providing reliable connectivity in remote areas. Additionally, in industrial settings, customized harnesses enable integration with specialized tools, boosting productivity while withstanding extreme conditions like vibrations and temperature fluctuations.

Key Performance Advantages

Customized wire harnesses offer significant benefits by optimizing electrical conductivity and reducing failure points. They minimize voltage drops and signal interference, leading to faster response times in critical systems like braking and navigation. Moreover, these configurations enhance durability through the use of high-grade materials that resist corrosion and abrasion, extending the lifespan of ATV and UTV electrical components. By ensuring precise fit and reduced clutter, they also improve heat dissipation and ease of maintenance, ultimately contributing to safer and more efficient vehicle operation in demanding environments.

Common Questions and Answers

1. What are the main components of a wire harness?

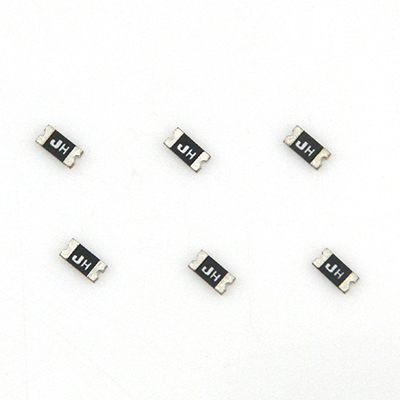

A wire harness typically includes wires, connectors, terminals, and protective sleeving, all designed to organize and protect electrical pathways in vehicles.

2. How do custom configurations improve safety in ATVs and UTVs?

They reduce the risk of short circuits and failures by using application-specific designs that handle environmental stresses, ensuring reliable performance during high-speed or rugged use.

3. What factors should be considered when selecting a wire harness?

Key factors include the vehicle’s electrical load, exposure to elements, and compatibility with existing systems to ensure long-term functionality and efficiency.