Industrial-Grade Wire Harness Parts for Forklift and Material Handler Electricals

News 2025-10-31

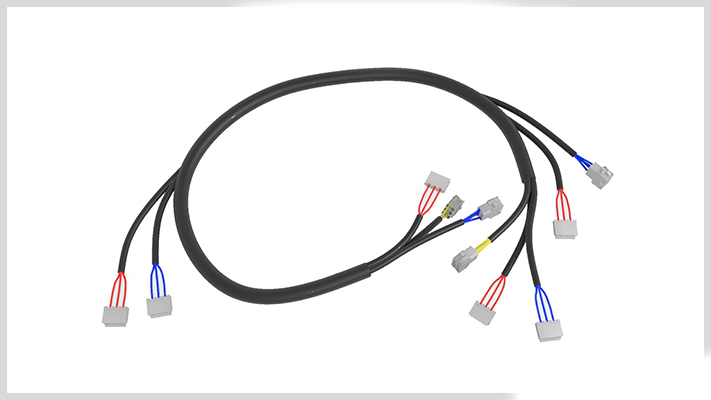

Wire harness parts are essential components in the electrical systems of industrial machinery, particularly forklifts and material handlers. These assemblies bundle multiple wires and cables, ensuring secure and efficient power and signal transmission. In the demanding environments of warehouses and manufacturing facilities, where equipment faces constant vibration, moisture, and heavy loads, industrial-grade wire harnesses provide the reliability needed to maintain operational uptime. By integrating high-quality materials and precise engineering, these parts reduce the risk of electrical failures, supporting safer and more productive workflows. As industries push for greater efficiency, selecting the right wire harness components becomes critical for optimizing the performance of forklift and material handler systems.

Performance Advantages

Wire harness parts offer significant performance benefits tailored to the rigors of industrial use. Constructed from robust materials like heat-resistant insulation and corrosion-proof connectors, they withstand extreme temperatures and chemical exposures common in forklift operations. This durability extends the lifespan of electrical systems, minimizing downtime and maintenance costs. Additionally, optimized designs improve electrical conductivity and reduce signal interference, enhancing the precision of control systems in material handlers. These advantages translate to better energy efficiency and lower operational risks, making wire harnesses a key factor in achieving high-performance standards in heavy-duty applications.

Common Applications

In practical settings, wire harness parts are integral to various scenarios involving forklifts and material handlers. For instance, in warehouse logistics, they facilitate the reliable operation of lifting mechanisms and navigation systems, ensuring smooth material movement in tight spaces. In manufacturing plants, these components support automated processes by connecting sensors and actuators, enabling precise handling of heavy loads. Furthermore, in outdoor environments like construction sites, wire harnesses provide protection against dust and moisture, maintaining functionality under adverse conditions. Overall, their versatility makes them indispensable for enhancing safety and efficiency across diverse industrial tasks.

Frequently Asked Questions

1. What materials are used in these wire harness parts?

They are typically made from high-grade copper wiring, PVC or rubber insulation, and metal connectors to ensure durability and resistance to environmental factors.

2. How do wire harnesses improve safety in forklifts?

By organizing wires and reducing exposure to damage, they prevent short circuits and electrical fires, contributing to safer operation in high-risk areas.

3. Are these parts customizable for different equipment?

Yes, they can be tailored in size, configuration, and specifications to fit various forklift and material handler models, ensuring optimal compatibility.