Inline Fuse Holder Featuring LED Fault Detection Capability

News 2026-01-12

An inline fuse holder featuring an LED fault detection capability is a valuable component in modern electrical and electronic protection schemes. By integrating a visual indicator directly into the fuse holder body, technicians can pinpoint a blown fuse instantly without interrupting power or resorting to complex diagnostic equipment. The compact design fits standard panel cutouts and supports multiple fuse types, offering flexibility across diverse installations. The LED remains illuminated under normal conditions and changes state the moment a fault emerges, streamlining maintenance procedures and trimming service time costs. Such fuse holders accommodate ratings up to 30 A and operate reliably over temperatures from –40 °C to +85 °C, meeting industry standards for vibration and flame retardancy.

Application Scenarios

In automotive dashboard circuits, these inline holders simplify maintenance by indicating fuse state at a glance. Marine and RV installations benefit from corrosion-resistant terminals and UV-stable housing, while renewable energy arrays leverage rapid fault detection to protect inverters and battery systems. Control panels in industrial machinery use these holders to minimize downtime during troubleshooting and to enhance operator safety by avoiding unexpected outages. Custom enclosures in telecommunications racks also integrate panel-mounted inline holders for real-time monitoring of branch circuits.

Performance Advantages

Visual fault indication cuts diagnostic times by up to 80 percent compared to traditional holders, reducing downtime and labor costs. Dual-color LEDs provide clear differentiation between normal and blown states, even in low-light areas. The low insertion resistance ensures minimal voltage drop under full load, while the glass-filled nylon body delivers superior impact strength. Gold-plated contacts resist oxidation and maintain consistent electrical performance, and the holder meets UL, CE and RoHS directives for global compliance.

Installation and Maintenance

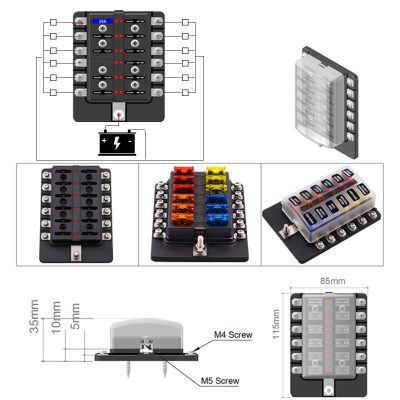

Engineers mount the fuse holder into a 12.7 mm panel cutout and secure it with a locking nut, requiring no special tooling. The design accommodates 16–12 AWG wiring, with captive terminal screws that prevent conductor loosening under vibration. Fuse replacement is tool-free: pull the housing cover, swap the blade fuse, then restore cover position. The LED diode is fully encapsulated to guard against moisture, and the clear lens offers 120° viewing angle. Periodic visual inspections suffice, eliminating complex test procedures.

Common Inquiries

1、What fuse ratings are compatible?

It accepts blade fuse sizes from 1 A up to 30 A, supporting both micro and mini form factors.

2、Can the LED be seen in bright light?

High-intensity LEDs maintain visibility under direct sunlight and harsh industrial lighting.

3、How is the fuse replaced?

Simply pull the housing cover, remove the spent fuse and insert a new one, then snap the cover back into place.