Key Diagnostic Clues Indicating Internal Fuse Box Component Failure In Modern Systems

News 2025-12-22

A fuse box that begins to fail internally rarely does so without warning. Subtle electrical irregularities appear long before a complete outage, especially in automotive, industrial, and building power distribution applications. Recognizing these early clues protects downstream electronic modules, prevents unscheduled downtime, and reduces the risk of thermal damage. Engineers and maintenance teams who understand how internal fuse box components deteriorate can schedule targeted inspections and replacements, optimizing system availability and safety.

Abnormal Voltage Behavior And Intermittent Operation

Unexpected voltage drops on protected circuits often point to high-resistance paths inside the fuse box, such as fatigued busbars, oxidized terminals, or cracked solder joints. Loads may flicker, control modules may randomly reset, and sensors may report unstable readings. When measurements at the load differ from those at the source by more than the specified tolerance, internal distribution faults become a prime suspect. In vehicle and industrial control cabinets, intermittent loss of critical subsystems—lighting, HVAC blowers, pumps, or PLC I/O rails—typically indicates that contact integrity in the fuse box has degraded rather than a single external device failure.

Thermal Hotspots, Odor, And Visual Degradation

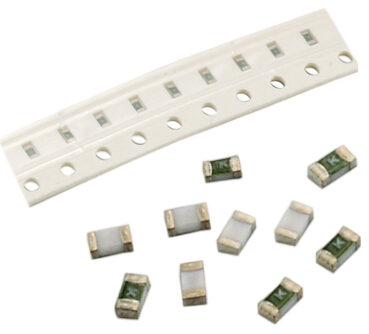

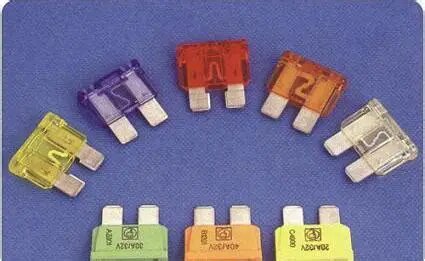

Localized heating is a core performance clue. Discolored plastic around fuse positions, softened housings, or faint burning odors often result from loose fuse blades or fatigued spring clips generating excessive contact resistance. Infrared thermography is a powerful diagnostic tool, quickly revealing hotspots around specific fuse ways or internal connectors under normal load. Brown or black marks, melted insulation, or visible warping highlight areas where internal conductive paths may be eroding. In high-current applications such as EV battery junction boxes or industrial motor feeders, these visual cues are strong indicators that internal components are close to functional failure.

Nuisance Blowing, Corrosion, And Environmental Stress

Frequent nuisance fuse blowing, especially when load measurements remain within specification, suggests internal faults rather than true overloads. Micro-arcing caused by worn contacts introduces transient surges that overstress fuses. In outdoor telecom cabinets, marine systems, and under-hood automotive environments, moisture and salt accelerate corrosion around terminals and busbars, raising resistance and heat. White or green deposits on metallic parts, cracked seals, or condensation patterns inside transparent covers signal compromised environmental protection. These signs imply that the internal architecture no longer provides the original performance margin, even if individual fuses still appear intact.

Impact On Application Performance And Replacement Criteria

Degraded internal components directly reduce system efficiency and reliability. Sensitive electronic modules may experience under-voltage, leading to erratic CAN bus communication, false fault codes, or unexpected resets. Motors can draw elevated current to maintain torque under reduced voltage, shortening lifespan. Where uptime is paramount—data centers, automated manufacturing lines, medical equipment—any pattern of intermittent operation, localized heating, or environmental contamination around the fuse box should trigger a structured evaluation and, when needed, full assembly replacement. Selecting modern fuse boxes with robust contact plating, enhanced sealing, and thermal-optimized layouts improves long-term stability and reduces diagnostic incidents.

1、What common field symptom points to internal fuse box failure?

Repeated intermittent power loss on the same circuit, without confirmed external wiring or load faults, often indicates deteriorated internal contacts or busbars.

2、How does environmental exposure affect fuse box performance?

Moisture, salt, and temperature cycling promote corrosion and mechanical fatigue, raising contact resistance and creating hotspots that accelerate internal component failure.

3、When should a fuse box be replaced rather than repaired?

If thermal damage, corrosion, or structural deformation is visible across multiple positions, replacement of the entire fuse box is safer and more cost-effective than localized repair.