Long-Lasting Thermal Fuse Guards Against Temperature-Related Electrical Failures In Demanding Systems

News 2025-11-27

Long-lasting thermal fuses are key safety components that interrupt current when temperatures exceed a defined threshold, preventing overheating, insulation breakdown, and fire hazards in electrical assemblies. Unlike resettable protectors, a thermal fuse permanently opens the circuit once a fault occurs, creating a clear, fail-safe condition that engineers can easily detect. Modern designs emphasize extended service life under continuous load, making them suitable for power supplies, battery packs, motor drives, household appliances, and industrial controllers that must endure harsh temperature cycles and fluctuating line conditions.

Core Operating Principle And Construction

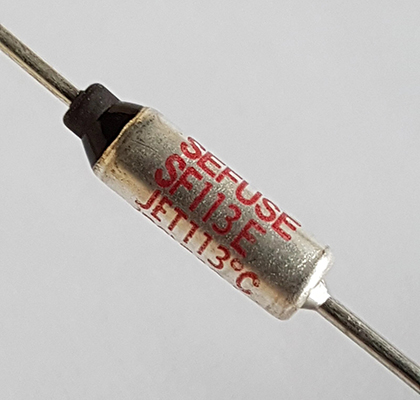

The long-lasting thermal fuse integrates a heat-sensitive pellet, alloy, or organic compound encapsulated in a compact, insulated housing. Under normal operating temperatures, the internal element maintains electrical continuity, enabling low-loss current flow. When ambient or component temperature rises beyond the rated cutoff value, the element melts or deforms, rapidly separating the conductive path. This irreversible action limits fault current at an early stage and lowers the risk of arcing or carbonization. The mechanical robustness of the housing, precise alloy formulation, and controlled manufacturing process collectively support long service life, stable opening temperature, and consistency across high-volume production.

Performance Advantages In High-Density Electronics

In dense PCB layouts and compact power modules, temperature gradients can be steep and unpredictable. A long-lasting thermal fuse offers a predictable and narrow tolerance band for opening temperature, helping designers maintain safe margins even under worst-case operating scenarios. Low internal resistance reduces self-heating, which protects neighboring components and improves overall conversion efficiency. Many product families support rated currents from a few hundred milliamps up to double-digit amperes at working voltages from low-voltage DC battery systems to universal AC mains, enabling uniform safety strategies across multiple product platforms. Durability against thermal cycling and vibration further reduces nuisance activation and field returns.

Key Application Scenarios And Integration Practices

These fuses appear in switched-mode power supplies, LED drivers, electric vehicle charging accessories, battery management systems, HVAC controls, coffee machines, washing machines, and motorized tools where hot spots can develop near transformers, MOSFETs, or mechanical loads. Engineers typically place the fuse in direct thermal contact with the heat source using clips, insulating sleeves, or adhesive tapes rated for high temperatures, ensuring fast and accurate response when abnormal conditions arise. The compact axial or radial leaded packages and surface-mount variants allow flexible routing, minimal PCB area usage, and straightforward integration into automated assembly processes while maintaining compliance with UL, VDE, and other safety standards.

Selection Criteria, Standards, And Lifecycle Benefits

When selecting a long-lasting thermal fuse, designers focus on cutoff temperature, hold temperature, rated current, rated voltage, and agency approvals. Matching the cutoff temperature to the actual maximum safe operating temperature of the host component helps avoid nuisance activation while still preventing damage. Compliance with UL, IEC, and regional safety regulations simplifies certification of end products in global markets. The extended operational lifespan of high-quality fuses reduces maintenance intervals and replacement costs in large installations, improves brand reputation, and supports warranty commitments by minimizing temperature-related electrical failures in the field.

1, What is the main function of a long-lasting thermal fuse in electronics?

It opens the circuit permanently when a preset temperature is exceeded, preventing overheating and reducing the risk of fire or component damage.

2, Where is this type of thermal fuse typically installed in a circuit?

It is installed in series with the load, often placed close to transformers, power semiconductors, or battery cells to sense dangerous hot spots quickly.

3, How does a long-lasting thermal fuse improve product reliability?

It offers stable opening characteristics, low internal resistance, and long service life, reducing nuisance trips and cutting down field failures caused by thermal stress.