Long-Term-Reliability Thermal Fuse Enhances Safety in Modern Electric Vehicles

News 2025-11-27

Long-term thermal protection components determine whether electronic systems in modern vehicles can maintain stable performance over hundreds of thousands of kilometers. A long-term-reliability thermal fuse is engineered to interrupt current once abnormal temperature is detected and to preserve that functional threshold over the full vehicle lifespan. This article examines how such fuses support safety, durability, and regulatory compliance in demanding automotive environments, especially in electrified powertrains, battery packs, and auxiliary systems.

Key Operating Principle And Design Characteristics

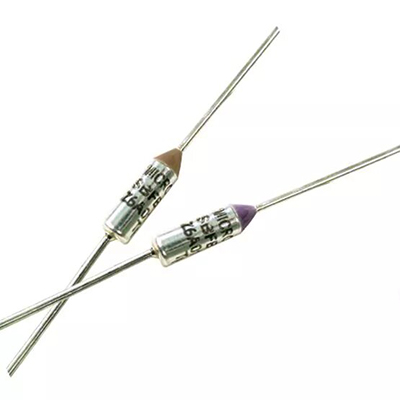

A long-term-reliability thermal fuse uses a precisely calibrated melting element or pellet that opens the circuit once its rated temperature is reached. Unlike resettable protectors, it provides a definitive cutoff to prevent overheating, fire, or catastrophic component failure. Automotive-grade designs emphasize tight opening-temperature tolerance, low contact resistance, and low leakage current. Robust encapsulation, vibration-resistant terminations, and stable contact materials help the fuse maintain consistent operation after long exposure to thermal cycling, humidity, and chemical vapors typical of under‑hood and battery environments.

Automotive Application Scenarios Across The Vehicle

In battery electric and hybrid vehicles, thermal fuses are embedded in high-energy lithium-ion modules to safeguard cells against internal short circuits or runaway conditions. They also protect on-board chargers, DC‑DC converters, traction inverters, and power distribution units that operate close to their thermal limits. Inside passenger cabins, these fuses are found in HVAC blowers, seat heaters, steering‑wheel heaters, infotainment head units, and USB power modules. Under the hood, they secure coolant pumps, radiator fans, and electronic control units, allowing designers to meet stringent safety and functional safety standards over prolonged operation.

Performance Advantages Over The Vehicle Lifespan

The main performance advantage of a long-term-reliability thermal fuse is that its opening temperature remains stable over many years of service. Materials are selected to resist drift caused by thermal aging, mechanical stress, and chemical attack, thereby preserving predictable trip behavior. Low internal resistance supports high energy efficiency and reduces self‑heating, while accurate time‑to‑open characteristics prevent nuisance operation during normal transient events such as inrush current or quick temperature spikes. These features reduce warranty claims, support longer service intervals, and enable downsizing of cooling systems and heat sinks in dense electronic assemblies.

Design-In Considerations And Standards Compliance

When integrating a thermal fuse into an automotive design, engineers evaluate operating temperature profiles, fault scenarios, and ambient conditions. Proper selection of cutoff temperature, current rating, and package style ensures coordination with upstream overcurrent devices and thermal management strategies. The device must be positioned where temperature accurately represents the most vulnerable component, often on battery tabs, power MOSFET packages, or transformer windings. Compliance with international safety standards and automotive quality requirements, including AEC‑Q testing where applicable, verifies performance under vibration, temperature shock, and long‑term endurance, supporting both homologation and OEM qualification.

Practical Q&A On Long-Term-Reliability Thermal Fuses

1. Where are these thermal fuses most frequently used in EVs?

They are widely used inside battery modules, power inverters, on‑board chargers, DC‑DC converters, and high‑current junction boxes to prevent overheating and protect costly semiconductor devices.

2. How does a thermal fuse differ from a resettable thermostat?

A thermal fuse provides a one‑time, permanent open circuit once its rated temperature is exceeded, while a thermostat or thermal switch resets automatically after the temperature falls, enabling repeated cycles.

3. What factors should engineers consider when choosing the cutoff temperature?

Engineers analyze worst‑case ambient temperature, self‑heating of nearby components, maximum safe temperature of cells or semiconductors, and required safety margin to select a fuse rating that trips only during genuine fault conditions.