Low-Profile Thermal Fuse Enhancing Compact Vehicle Electronic Safety and Space Efficiency

News 2025-11-27

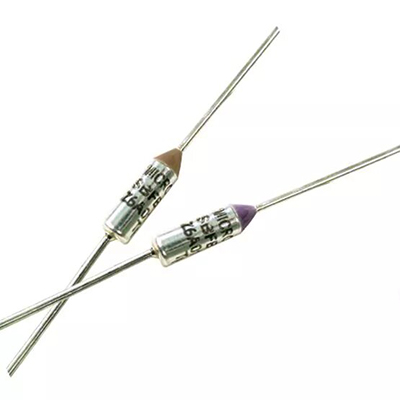

Low-profile-design thermal fuse fits discreetly in compact vehicle electronics, addressing the demand for higher safety in ever-smaller control modules. As vehicle platforms integrate more power-dense ECUs, sensor hubs, and infotainment units, thermal protection must occupy minimal PCB real estate while maintaining strict automotive compliance. This article highlights how a low-height thermal fuse architecture supports downsized designs, improves assembly flexibility, and safeguards against abnormal overtemperature in confined environments.

Key Design Features of the Low-Profile Thermal Fuse

The core characteristic of the low-profile thermal fuse is its extremely small height, enabling placement under shielding cans, stacked boards, or near densely packed connectors. Metal-alloy, organic pellet, or polymer-based fusible elements are encapsulated in a slim housing that keeps thermal mass low, so response to overheating remains fast and consistent. Rated opening temperatures can be selected across a broad range, supporting applications from low-power signal electronics to high-current power distribution modules. Automotive-grade variants typically meet AEC-Q200 or equivalent standards, supporting high vibration endurance, extended temperature cycling, and long-term electrical stability.

Application Scenarios in Modern Vehicle Electronics

The low-profile fuse is particularly suited to compact ECUs in ADAS cameras, radar modules, and LiDAR processing units where PCB space is at a premium. It protects DC/DC converter stages, LED drivers, and power rails that feed image sensors and microcontrollers, interrupting current once enclosure temperature exceeds defined safety thresholds. In body electronics such as window lift controllers, seat modules, ambient lighting, or smart switch panels, the fuse mitigates thermal runaway caused by wiring faults or blocked ventilation. High-density infotainment systems, head-up displays, and connectivity gateways also benefit from discrete placement near localized heat sources, maintaining occupant safety and electronics reliability under heavy load or hot climate operation.

Performance Advantages and System-Level Benefits

Compared with traditional radial or bulky axial thermal fuses, the low-profile design reduces shadowing and improves airflow within dense enclosures, helping designers maintain uniform temperature distribution. Its flat form factor typically supports automated SMT assembly, lowering production cost and improving placement accuracy on high-layer PCBs. Short thermal paths enable rapid reaction to abnormal heat events, which helps prevent PCB charring, connector deformation, and damage to costly ICs. The compact fuse also simplifies layout optimization, freeing space for additional protection devices, filtering components, or diagnostic circuitry, while retaining robust isolation performance, low contact resistance, and predictable fusing characteristics across the specified automotive temperature range.

Integration, Compliance, and Design Considerations

When integrating a low-profile thermal fuse, engineers must carefully position it near likely hot spots such as power MOSFETs, linear regulators, or high-current traces, while avoiding thermal coupling from normal operation that could cause nuisance trips. Coordination with upstream overcurrent protection ensures that the fuse responds specifically to overtemperature rather than brief inrush events. Designers typically evaluate derating curves, reflow soldering profiles, and mechanical clearance to meet OEM assembly rules and IP protection requirements. Compliance testing may include thermal aging, surge conditions, and vibration stress in accordance with automotive safety and functional standards, ensuring the fuse performs consistently across the full service life of the vehicle.

FAQ on Low-Profile Thermal Fuse Applications

1. Where is a low-profile thermal fuse most commonly used in vehicles?

It is widely used in compact ECUs, ADAS camera modules, infotainment systems, and body electronics where space is limited and localized thermal protection is required.

2. How does the low-profile design improve PCB layout?

The flat housing allows placement under shields or in tight gaps, reduces interference with airflow, and enables more flexible routing and component density on multilayer boards.

3. What parameters should engineers focus on during selection?

Key parameters include opening temperature, current rating, voltage rating, AEC-Q compliance, soldering profile compatibility, and the thermal coupling between the fuse and the protected heat source.