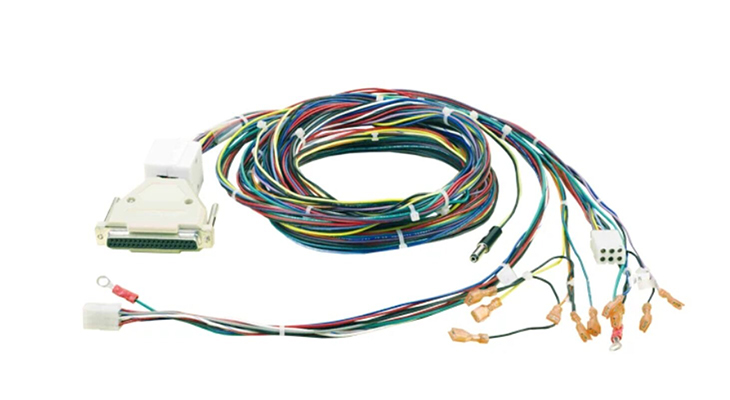

Robust Wire Harness Structures for Automotive Fuel Injector and Pump Electrical Connections

News 2025-10-31

In the automotive industry, wire harnesses play a crucial role in ensuring reliable electrical connections for components like fuel injectors and pumps. These structures must withstand harsh conditions such as vibrations, temperature extremes, and chemical exposures to maintain vehicle performance and safety. As automotive systems evolve with electrification and advanced fuel technologies, robust wire harness designs become essential for preventing failures that could lead to inefficiencies or breakdowns. This article explores how specialized wire harness constructions enhance durability and functionality in fuel system applications.

Key Application Scenarios

Wire harnesses for fuel injectors and pumps are critical in various automotive contexts, including gasoline, diesel, and hybrid vehicles. In high-performance engines, they facilitate precise electrical signals for optimal fuel delivery, improving combustion efficiency and reducing emissions. For instance, in electric fuel pumps, these harnesses handle high-current loads while resisting moisture and fuel vapors, ensuring consistent operation in engine compartments. Additionally, in modern EVs with integrated fuel systems, robust designs support diagnostic communications, enabling real-time monitoring and maintenance, which is vital for compliance with stringent environmental regulations.

Performance Benefits

The design of wire harnesses focuses on materials and configurations that offer superior resistance to wear and environmental factors. Using high-grade insulators and corrosion-resistant conductors, these structures minimize signal interference and extend component lifespan. Enhanced flexibility allows for better routing in tight spaces, reducing stress points that could cause shorts or breaks. Moreover, advanced sealing techniques protect against contaminants, leading to improved reliability in demanding conditions. This results in lower maintenance costs and enhanced safety, as stable electrical connections prevent issues like injector misfires or pump failures that could affect vehicle handling.

Frequently Asked Questions

1. What materials are used in robust wire harnesses?

Materials include high-temperature polymers for insulation and copper alloys for conductors, providing durability against heat and corrosion.

2. How do these harnesses improve fuel system efficiency?

By ensuring secure electrical connections, they reduce energy loss and enable precise control of fuel delivery, optimizing engine performance.

3. What testing is involved in their development?

Rigorous tests for vibration, thermal cycling, and fluid resistance are conducted to meet automotive standards and ensure long-term reliability.