Maintenance Habits That Greatly Extend Electrical Fuse Box Service Life

News 2025-12-22

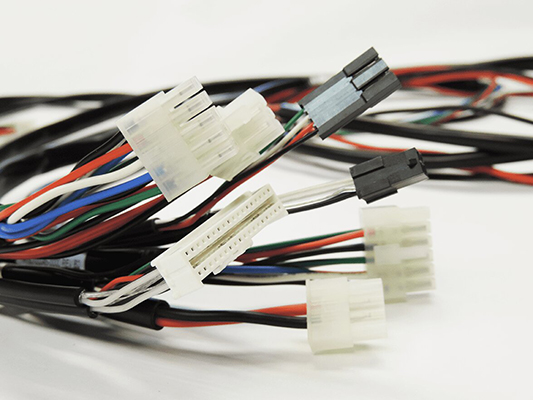

Long‑term stability of a fuse box depends less on its rated current and more on daily maintenance habits. In industrial cabinets, commercial switchboards, and residential distribution panels, consistent care protects downstream electronics, prevents nuisance trips, and reduces thermal stress on conductors. A well‑maintained fuse box delivers predictable protection, supports higher uptime, and keeps voltage distribution clean for sensitive loads such as PLCs, communication modules, LED drivers, and precision power supplies.

Keep Contacts Clean And Tight

Clean, tight connections are the foundation of fuse box longevity. Dust, oil mist, and conductive particles accumulate on terminals inside factory environments and data centers, leading to micro‑arcing and localized heating. Regularly de‑energize the panel, remove fuses, and inspect clips, busbars, and terminal screws. Use non‑residue electrical contact cleaner and lint‑free swabs to remove oxidation. Re‑torque terminal screws according to manufacturer specifications to prevent loose joints that raise impedance. These practices maintain low contact resistance, reduce energy loss, and sustain stable performance under rated short‑circuit conditions.

Control Temperature And Load Distribution

Thermal management strongly influences fuse box service life in high‑density industrial racks and HVAC control panels. Monitor internal temperature using built‑in sensors or external thermal labels and keep operating ranges safely below fuse element derating thresholds. Balance loads across phases and circuits, avoiding sustained operation above 80% of rated current. Add ventilation grilles, panel fans, or climate‑controlled enclosures in hot machine rooms. Proper load distribution and cooling lower cumulative thermal stress on fuse elements, clips, and insulation, enhancing breaking capacity stability and reducing premature fuse fatigue.

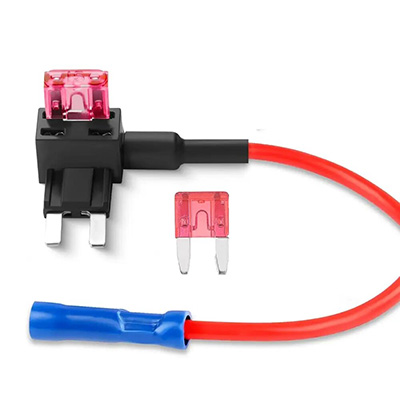

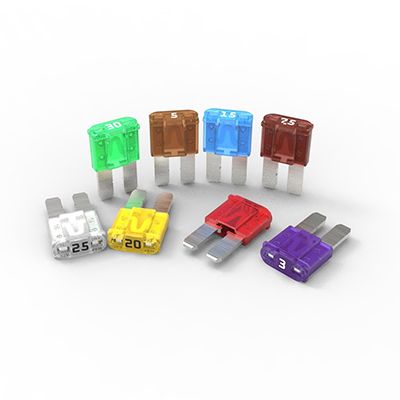

Schedule Inspections And Replace Ageing Components

Preventive inspection cycles should be aligned with equipment criticality. For production lines, quarterly visual checks and annual detailed inspections are standard best practice. Look for discoloration, melted plastic, cracking insulation, or corrosion on terminals. Replace fuses showing any mechanical damage, even if they have not blown, and always use types that match the original interrupt rating, voltage class, and time‑current curve. Periodically renew fuse holders, DIN‑rail blocks, and labels to keep circuit identification clear. Such disciplined replacement avoids unsafe improvisations on site and maintains the fuse box’s original protection profile.

Document Maintenance And Adapt To Application Scenarios

Accurate records transform simple routines into a robust maintenance strategy. Log fuse ratings, replacement dates, measured currents, ambient temperatures, and any tripping incidents. In renewable energy systems, EV charging infrastructure, and server rooms where load patterns change quickly, use these logs to reassess fuse coordination and select products optimized for high inrush or frequent cycling. Documented maintenance proves compliance during audits, supports safety certifications, and allows engineers to fine‑tune selectivity between upstream breakers and downstream fuses, improving both protection performance and overall power quality.

1、How often should an industrial fuse box be inspected?

Quarterly visual inspections and annual in‑depth checks are recommended for most industrial and commercial installations, with shorter intervals in harsh or high‑load environments.

2、Why is load balancing important to fuse box life?

Balanced loads prevent chronic overheating of specific poles or circuits, reducing thermal stress on fuse elements and terminals while improving overall energy efficiency.

3、What signs indicate components need replacement?

Discoloration, burnt odor, warped plastic, pitted contacts, and recurring fuse operations on the same circuit signal that fuses or holders should be replaced and load conditions reviewed.