Map light fuse safeguards modern interior map light and reading lamp systems

News 2025-11-17

Map light fuse safeguards map light and reading light systems play a key role in protecting low‑voltage automotive interior lighting. Located in the vehicle fuse box, this dedicated fuse isolates the map and reading lamp circuits from supply anomalies, wiring faults, or incorrect bulb replacement. By interrupting excessive current in milliseconds, it prevents harness damage, switch overheating, and localized cabin fires while keeping the rest of the body electronics fully operational.

Function and electrical performance characteristics

The map light fuse is engineered to match typical 12 V or 24 V electrical architectures used in passenger cars, buses, and commercial vehicles. Rated currents usually fall between 5 A and 15 A depending on LED or halogen loads, dimming modules, and multiplexed control units. Time‑current curves are precisely defined: the fuse tolerates harmless inrush peaks from LED driver capacitors yet opens quickly during sustained shorts or overloads. Low internal resistance reduces voltage drop, protecting luminous efficacy of reading lights while minimizing heat rise in the fuse cavity.

Application scenarios in modern vehicle interiors

In practice, a map light fuse protects a wide range of interior lighting zones, including front dome map lights, rear passenger reading lamps, vanity mirror lights, and in some designs ambient accent strips near the headliner. High‑end vehicles often route multiple LED arrays, touch‑sensitive switches, and CAN‑controlled modules through a shared fuse channel, leveraging its fast‑acting behavior to secure complex lighting layouts. When a connector is mis‑mated during service or a metallic object causes a short in the overhead console, the fuse isolates the fault so that other comfort and infotainment loads continue operating without interruption.

Performance advantages and design considerations

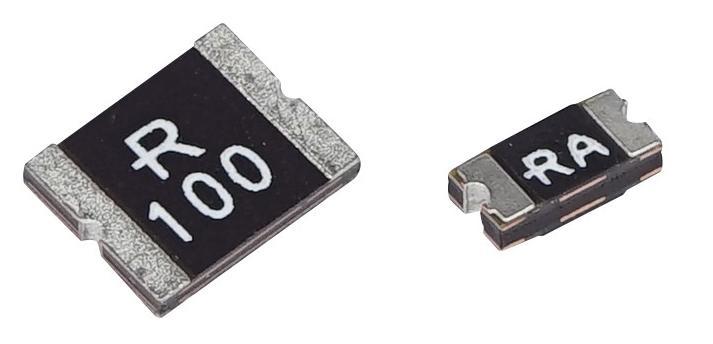

Engineers select map light fuses that offer tight tolerance of melting characteristics, high vibration resistance, and stable performance over the full automotive temperature range. Blade‑type fuses are common due to their compact footprint and standardized ratings, enabling easy replacement by service technicians or end users. Using a dedicated fuse rather than sharing lines with other interior loads improves troubleshooting, supports modular wiring harness design, and reduces the risk that a single failure disables multiple critical cabin functions. Proper coordination with upstream protection, wiring gauge, and LED driver limits ensures that the fuse remains the defined weak link in the circuit.

Maintenance, diagnostics, and typical failure modes

In routine maintenance, technicians verify map light fuse integrity whenever interior lamps fail while other cabin features still operate correctly. A blown fuse typically indicates a shorted bulb holder, damaged overhead console wiring, or incorrect aftermarket accessory installation. Replacement must always match the original current rating and type; oversizing the fuse can lead to wire overheating and severe safety hazards. Diagnostic workflows increasingly rely on body control module fault codes and current monitoring, yet the physical fuse remains a straightforward and cost‑effective protective device that can be quickly inspected, replaced, and documented in service records.

1、What happens when the map light fuse blows?

The protected map and reading lights stop working, but other interior and exterior systems usually remain unaffected, making fault isolation easier and preventing broader electrical damage.

2、Can a higher‑rated fuse be used to prevent repeated blowing?

Using a higher rating is unsafe because it allows excessive current through wiring and connectors; the proper fix is locating the underlying short or overload and then reinstalling a fuse of the specified value.

3、How does LED technology influence map light fuse selection?

LED map lights draw lower steady‑state current yet can create brief inrush peaks; designers therefore use fuses whose time‑current curves handle these transients while still disconnecting quickly during genuine faults.