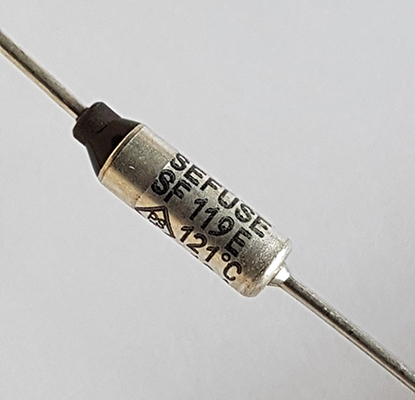

Precision-Calibrated Thermal Fuse Ensures Exact Temperature Intervention in Demanding Circuits

News 2025-11-27

Precision-calibrated thermal fuses provide accurate, single-action overtemperature protection in compact electronic assemblies. By using a carefully engineered alloy or organic pellet that opens the circuit at a defined temperature point, these fuses prevent overheating, component damage, and potential fire hazards. Unlike generic thermal protectors, they are factory-set to trigger at an exact temperature, allowing designers to match the cutoff point to the thermal profile of the application. This balance between safety margin and operational flexibility makes them an integral part of high-density power and signal systems where consistent performance is mandatory.

Operating Principle and Calibration Accuracy

Precision thermal fuses contain a temperature-sensitive element that changes state when the rated cutoff temperature is reached. Once this element melts or reacts, spring tension or mechanical separation opens the circuit permanently, isolating downstream components. During production, each fuse is calibrated through controlled heating and stringent tolerance checks, often within ±5 °C or tighter. Such accuracy is vital in power supplies, chargers, LED drivers, and industrial controls where a few degrees can separate safe operation from destructive thermal runaway. The precise trigger point also reduces nuisance interruptions, which is important in systems expected to run continuously under fluctuating loads.

Performance Advantages in Modern Electronics

A key advantage of a precision-calibrated thermal fuse is predictable, repeatable behavior across large production runs. Low resistance in the conducting state minimizes power loss and heat generation, which supports higher efficiency in compact designs. Many models are rated for high interrupting current, enabling them to safely open under fault conditions such as short circuits or stalled motors. Their encapsulated construction resists vibration, humidity, and contamination, enhancing long-term stability. Compliance with international safety standards and agency approvals helps manufacturers accelerate certification of appliances, communication equipment, and industrial power modules while maintaining strict protection levels.

Application Scenarios and Design Integration

These fuses are widely used in AC adapters, lithium-ion battery packs, HVAC controllers, coffee machines, dishwashers, medical devices, and EV charging accessories. In high-density power modules, designers typically place the fuse close to the hottest component—such as a MOSFET, transformer, or power resistor—to ensure fast reaction to localized hotspots. In battery packs, a fuse calibrated near the cell manufacturer’s maximum safe temperature prevents thermal runaway without unnecessarily limiting charge and discharge rates. When integrating the fuse, engineers must consider ambient temperature, airflow, PCB copper area, and thermal coupling so the actual operating conditions match the intended cutoff point. Proper selection of voltage rating, current rating, and insulation class further guarantees safe operation.

Selection Guidelines and Deployment Best Practices

Choosing the right thermal fuse begins with defining the maximum allowable component or system temperature and the expected operating range. The cutoff value should sit above the highest normal temperature but below the threshold where insulation, electrolytic capacitors, or semiconductor junctions degrade. Designers should review time-to-open curves under various overload levels, ensuring adequate protection during both slow, cumulative heating and sudden fault events. Using a fuse from a manufacturer that offers detailed datasheets, traceable calibration, and batch-level testing improves product consistency. During production, avoiding excessive soldering heat and providing proper mechanical support prevents performance drift. Periodic validation in accelerated life tests ensures that long-term aging does not shift the opening temperature beyond design limits.

FAQs on Precision-Calibrated Thermal Fuses

1How does a precision thermal fuse differ from a thermostat?

A thermal fuse is a non-resettable, one-shot safety device that permanently opens the circuit at its rated temperature, whereas a thermostat or thermal switch is typically resettable and intended for regular temperature control rather than final protection.

2Where are precision-calibrated thermal fuses most commonly used?

They are widely deployed in power adapters, battery packs, household appliances, lighting drivers, and industrial control units where strict overtemperature protection and compliance with safety standards are required.

3What factors should be considered when choosing the cutoff temperature?

Key considerations include the maximum normal operating temperature, component thermal limits, safety margins mandated by standards, airflow conditions, and the location of the fuse relative to heat sources in the assembly.