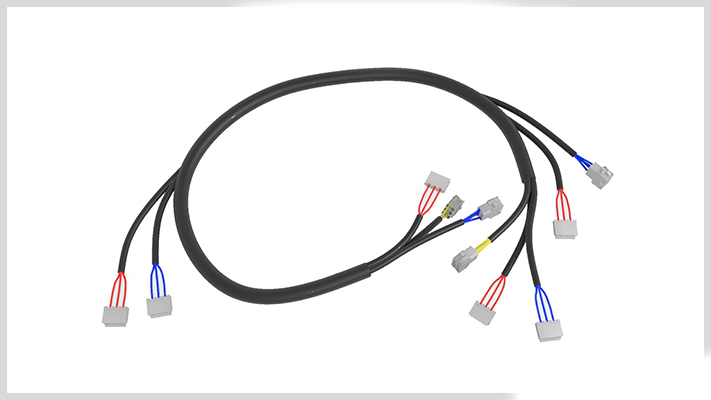

Precision Wire Harness Engineering for Automotive Lighting and Electronic Integration

News 2025-10-31

Wire harness designs are fundamental to the automotive industry’s advancements in lighting and electronics, providing structured electrical pathways that enhance system performance. These components integrate seamlessly with vehicle architectures, supporting features like adaptive headlights and sensor networks. By focusing on efficient connectivity, wire harnesses reduce complexity in assembly and improve overall vehicle reliability, making them essential for modern automotive applications.

Key Performance Advantages

Engineered wire harnesses deliver superior performance through innovative material choices and design strategies that minimize weight and maximize durability. They offer excellent resistance to vibration, temperature extremes, and chemical exposure, which is vital for components in harsh environments. This results in lower maintenance needs and extended service life, while optimized routing reduces electromagnetic interference, ensuring clear signal transmission for critical systems like collision avoidance and lighting controls.

Diverse Application Scenarios

In automotive lighting, wire harnesses enable precise control of LED and halogen systems, adapting to driving conditions for better visibility and safety. For electronics, they facilitate integration with infotainment, navigation, and autonomous features, allowing data exchange between modules. Applications extend to electric vehicles, where harnesses manage high-voltage circuits for batteries and motors, supporting energy-efficient operations and contributing to sustainable mobility solutions across passenger cars, commercial fleets, and emerging tech.

Common Questions and Answers

1. What is the role of wire harnesses in vehicle electronics?

They organize and protect wiring, ensuring efficient power and data flow for systems like infotainment and sensors.

2. How do these designs enhance lighting performance?

By using durable materials and precise configurations, they maintain consistent illumination and reduce energy consumption in lighting arrays.

3. What factors influence wire harness durability?

Factors include material quality, environmental resistance, and design layout, which collectively extend the lifespan under operational stresses.