Proper Inline Fuse Holder Installation Requirements and Common Errors

News 2026-01-12

In modern automotive and marine electrical systems, inline fuse holders serve a crucial safety function by protecting circuits against overcurrent events. Proper installation enhances system resilience, while a flawed setup introduces failure risks. This overview examines application scenarios for automotive wiring, solar power arrays, and audio installations. It outlines precise installation workflows, highlights performance advantages of low-resistance contacts, and offers a structured approach to help technicians and hobbyists implement protection devices accurately.

Required Tools and Materials

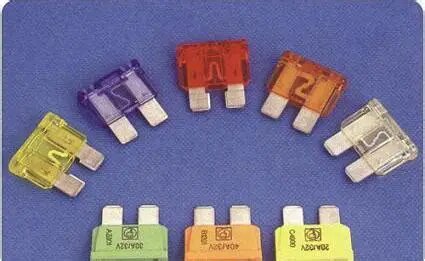

Successful inline fuse holder installation depends on assembling the right equipment. A compatible fuse holder paired with an automotive blade fuse forms the core. Use wire strippers to trim insulation cleanly and a crimping tool to secure terminals. Choose ring or spade connectors sized to match wire gauge. Employ a multimeter to verify continuity and confirm voltage levels. Heat-shrink tubing combined with a heat gun seals joints against moisture. Cable ties and mounting clips stabilize the assembly to prevent vibration-induced stress.

Installation Workflow

Begin by planning the fuse holder location near the battery or power source while maintaining accessibility. Cut the positive supply line and strip each conductor to about a quarter inch. Insert stripped ends into the fuse holder terminals and crimp firmly, ensuring metal-to-metal contact. Slide heat-shrink tubing over the joint and apply heat evenly until it contracts. Mount the holder securely using clips or zip ties to minimize movement. After inserting an appropriately rated fuse, test the line with a multimeter for proper continuity and correct voltage under load before restoring full power.

Avoidable Installation Errors

Several common mistakes can undermine fuse holder performance. Using the wrong fuse rating may allow overload currents to pass or blow unnecessarily. Poor crimp quality or loose connections increase resistance, leading to heat buildup. Skipping strain relief leaves terminals vulnerable to wire fatigue. Ignoring environmental factors such as moisture and vibration accelerates corrosion and contact failure. To prevent these issues, select the correct fuse amperage, use professional-grade crimp tools, apply dielectric grease, secure cables firmly, and verify each connection with diagnostic equipment before operation.

Performance Benefits and Application Scenarios

Inline fuse holders offer rapid fault isolation, protecting sensitive components in automotive circuits, marine power systems, solar panels, and custom audio installations. Low-resistance contacts preserve voltage stability under high loads, while easily replaceable fuses reduce maintenance time. When installed correctly, these devices act as the first line of defense against short circuits and current spikes, enhancing equipment longevity. Compact footprints allow integration in tight control panels or under dashboards, providing versatile protection across a broad range of electronics and power distribution setups.

1、What fuse rating is recommended?

A fuse rating should match the circuit’s maximum current draw plus a 25% margin to prevent nuisance blows and ensure protective reliability.

2、Can I reuse a blown fuse?

A fuse that has melted cannot be restored; always replace it with the same type and rating to maintain circuit safety.

3、Where should the fuse holder be mounted?

Position the inline fuse holder close to the power source in an accessible, dry location, using secure mounting to minimize vibration exposure.