Shock-Proof Thermal Fuse Ensures Safe Operation In Demanding Vehicle Environments

News 2025-11-27

Modern electric and hybrid vehicles expose protection components to intense vibration, rapid temperature shifts, and high current surges. A shock‑proof thermal fuse engineered for automotive conditions maintains its cut‑off accuracy even during harsh road impacts, preserving both passenger safety and powertrain integrity. By combining tight thermal tolerance with mechanical robustness, this fuse helps engineers meet stringent safety standards while supporting compact, high‑power system design.

Design Features That Prevent Nuisance Tripping

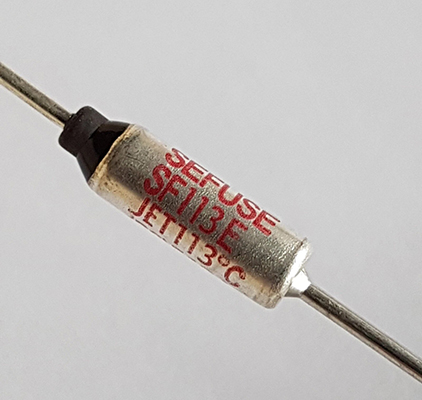

The shock‑proof thermal fuse uses a reinforced housing and vibration‑damped internal structure that protects the temperature‑sensitive pellet and spring mechanism from mechanical shock. Contact geometry is optimized to prevent micro‑movement that could cause resistance drift or premature opening. Stable calibration ensures the fuse opens only at the defined trip temperature, even under continuous vibration or sudden impact typical of potholes, off‑road conditions, or high‑speed driving. Low internal resistance minimizes self‑heating, allowing accurate response to the actual equipment temperature rather than transient current peaks.

Automotive Application Scenarios

This component fits a broad range of vehicle subsystems where both thermal overload and mechanical stress are present. Typical uses include battery pack modules, on‑board chargers, DC‑DC converters, inverters, cabin heaters, seat heaters, and motor windings in pumps or fans. In traction battery packs, the fuse guards against thermal runaway caused by cell imbalance or cooling failure. In power electronics, it acts as a final safety barrier when active monitoring or software control cannot react quickly enough. The compact footprint supports high‑density assemblies in confined compartments such as under‑seat modules and engine bays.

Performance Advantages In Harsh Environments

The shock‑proof thermal fuse is qualified across extended temperature ranges and high vibration levels defined by automotive standards. Fast response time reduces damage to wiring, connectors, and semiconductor devices during fault conditions. Stable performance over long service life lowers maintenance costs and warranty risk. Compatibility with automated soldering and spot‑welding processes simplifies integration into mass production. By avoiding false trips under shock events, the fuse improves system uptime and reduces unnecessary service visits, which is crucial for fleets, commercial vehicles, and high‑mileage passenger cars.

Selection Considerations And Integration

When selecting a shock‑proof thermal fuse, engineers evaluate rated current, opening temperature, interrupting capacity, and insulation class. Placement close to the hottest potential failure point ensures a predictable response. Proper mechanical fixation prevents stress on terminals that might alter calibration. Coordination with upstream circuit breakers and downstream wiring is important so that the fuse operates as the final protective element without interfering with normal transient loads. Detailed datasheets and test reports, including vibration and thermal cycling results, support compliance documentation and speed up design approval.

1. Typical automotive standards

The fuse can be designed to align with AEC‑Q200‑like testing as well as OEM‑specific vibration, thermal shock, and humidity requirements.

2. Compatibility with EV battery systems

Yes. It is suitable for cell‑level, module‑level, or pack‑level protection, particularly where mechanical shock and thermal overload can occur simultaneously.

3. Maintenance requirements

The device is non‑resettable. Once it opens, the affected module must be serviced or replaced, which ensures that serious thermal faults are fully investigated before returning the vehicle to service.