Shock-Resistant Thermal Fuse Ensures Continuous Protection During Demanding Vehicle Operation

News 2025-11-27

Thermal fuses designed for automotive environments must endure vibration, sudden shocks, and temperature cycling while preserving precise cut-off characteristics. A shock-resistant thermal fuse tailored to vehicle operation addresses these simultaneous demands by combining robust mechanical construction and tightly controlled melting temperature. It acts as a one-time, fail-safe protection element, interrupting current when abnormal heat occurs in wiring harnesses, battery packs, or power electronics. By maintaining stability under harsh conditions, it helps prevent overheating, insulation damage, and fire hazards in combustion, hybrid, and electric vehicles.

Key Automotive Application Scenarios

Shock-resistant thermal fuses are widely used in electric power steering systems, ABS/ESC control units, engine control modules, and transmission electronics, where vibration is continuous and temperature fluctuations are frequent. In electric vehicles, they protect on-board chargers, DC/DC converters, battery management systems, and high-voltage junction boxes. The devices are also integrated into seat heaters, blower motors, window defoggers, and infotainment units to disconnect faulty loads before critical temperatures are reached. Their compact footprint supports dense PCB layouts in control units located close to engines, in wheel wells, or near high-current busbars.

Performance Advantages Under Shock and Vibration

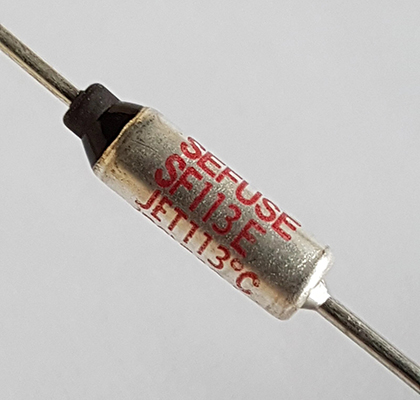

The shock-resistant structure typically uses reinforced lead welding, rigid encapsulation, and internal support elements that prevent mechanical fatigue or contact displacement during acceleration, braking, and road impact events. This stability keeps the rated opening temperature and current consistent across the entire vehicle lifetime. Low contact resistance minimizes self-heating, improving power efficiency in high-current lines. Automotive-grade versions are tested under random vibration and mechanical shock profiles aligned with industry standards, ensuring dependable opening even after prolonged exposure to harsh road conditions, potholes, or off-road use.

Design Integration, Standards, and Safety Compliance

Engineers can select fuses by opening temperature, rated current, voltage, and package style to match specific harness sections and electronic control units. Radial-leaded and axial-leaded versions allow flexible PCB or in-line mounting, while clearly defined derating curves support accurate thermal design in confined spaces. Many shock-resistant thermal fuses comply with AEC-Q200 or similar automotive qualification requirements, as well as UL and IEC safety standards. Clear labeling, traceability codes, and datasheet support simplify design validation and quality audits. By offering predictable behavior under combined thermal, electrical, and mechanical stress, these components significantly enhance functional safety in modern vehicles.

FAQ: Shock-Resistant Thermal Fuse in Vehicles

1. Where is a shock-resistant thermal fuse typically installed in vehicles?

It is commonly placed in power distribution modules, battery lines, charger circuits, and near heat-critical loads such as heaters and motor drives.

2. How does it differ from a standard thermal fuse?

The shock-resistant type is engineered to maintain calibration under vibration and impact, ensuring the opening temperature remains accurate throughout vehicle use.

3. Can it be reset after opening once?

No. Once the thermal fuse opens at its specified temperature, it must be replaced to restore the circuit, providing a fail-safe protection approach.