Specialty Fuse Custom Design Addresses Specific Vehicle Electrical Needs In Modern Mobility

News 2025-11-17

Specialty fuse custom design addresses specific vehicle electrical needs

Tailored protection for complex automotive architectures

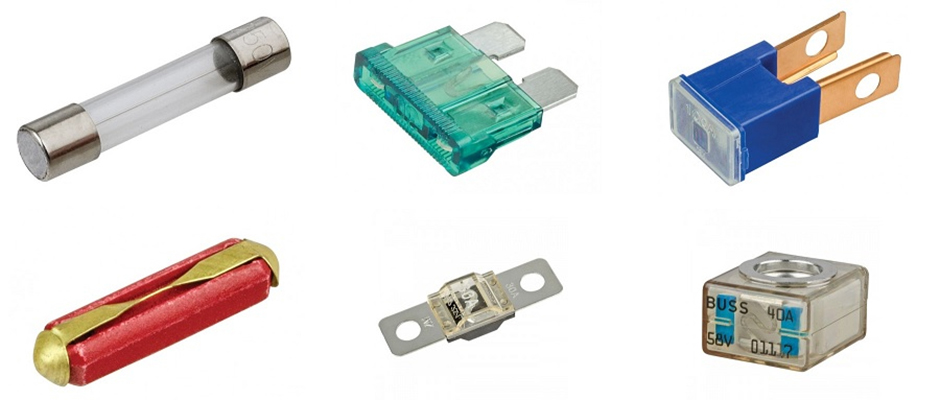

Modern vehicles integrate dense power distribution networks, high-current loads, and increasingly sensitive electronics. Standard catalog fuses often cannot match the precise trip curves, packaging constraints, and lifetime requirements demanded by these platforms. Custom-designed specialty fuses enable engineers to align interrupt ratings, voltage classes, and melting characteristics with real-world load profiles, from start-stop surges to steady auxiliary currents. By collaborating early in the design cycle, automakers and tier suppliers can specify fuse geometry, terminal style, and mounting method that support compact junction boxes and multi-layer busbar systems, while maintaining stringent safety margins under extreme temperature and vibration.

Performance attributes that enhance vehicle safety and durability

A specialty fuse designed around a specific vehicle program optimizes both protection speed and selectivity. Precise I²t coordination helps ensure that only the intended branch circuit clears during a fault, preserving continuity to safety-critical modules such as steering, braking, and ADAS controllers. Advanced alloy fuse elements, calibrated neck-down sections, and carefully controlled sand filling improve arc quenching, limiting let-through energy and preventing damage to wiring insulation or downstream semiconductors. Engineers can specify slow-blow characteristics for motor-driven loads, or fast-acting profiles to protect sensitive ECUs and power electronics, creating a right-sized protective envelope that extends service life and reduces warranty incidents.

Application scenarios across ICE, hybrid, and EV platforms

Custom specialty fuses play a central role in diverse automotive applications. In internal combustion platforms, they protect starter circuits, cooling fans, fuel pumps, and comfort systems, often housed in under-hood fuse boxes exposed to high ambient temperatures. Hybrid and plug-in vehicles require carefully engineered fusing in DC/DC converters, on-board chargers, and battery junction boxes, where high fault currents and limited space challenge conventional solutions. Battery electric vehicles depend on high-voltage fuses tailored to traction inverters, on-board chargers, and auxiliary 12 V networks, balancing compact footprints against high interrupt capacities. OEM-specific form factors support automated assembly and robust connection integrity, improving overall system efficiency and serviceability.

Design customization, validation, and OEM integration

The development process for a specialty automotive fuse combines electrical modeling, material science, and rigorous validation. Design teams analyze inrush events, transient overloads, and worst-case short-circuit conditions to define time-current characteristics that match the vehicle’s load map. Customization may include blade, bolt-on, or plug-in styles, color coding aligned with OEM standards, and branding elements that simplify identification in global service networks. Prototypes undergo thermal aging, vibration, mechanical shock, and salt-spray testing to meet automotive standards such as ISO and LV specifications. Close integration with OEM engineering teams ensures that fuses are optimized not only for protection but also for manufacturability, diagnostics, and long-term availability.

Future trends in smart protection and diagnostics

Growing adoption of software-defined vehicles increases demand for protection components that support advanced diagnostics. Specialty fuses can be designed to interface with smart junction boxes, allowing current sensing or status monitoring through companion electronics. This approach helps technicians locate faults faster and improves uptime in fleets and commercial vehicles. As power levels rise in fast-charging and high-performance EVs, custom fuses will continue to evolve in materials, arc management, and thermal performance, ensuring precise fault isolation while preserving compact packaging.

1. What vehicle systems benefit most from custom fuse design?

Power distribution units, high-voltage battery circuits, starter and traction systems, ADAS modules, and body electronics benefit significantly, gaining tailored protection, reduced nuisance blows, and improved long-term reliability.

2. How does a specialty fuse improve maintenance in the field?

Application-specific ratings, clear marking, and consistent form factors simplify diagnostics and replacement, while well-coordinated trip curves reduce collateral damage, lowering repair time and lifecycle costs.

3. Are custom fuses suitable for commercial and off-highway vehicles?

Yes, specialty fuse designs can be optimized for heavy-duty trucks, buses, agricultural and construction equipment, addressing higher vibration, harsher environments, and extended duty cycles.