Superior Wire Harness Parts Engineered for Automotive Mass Airflow Sensor Electrical Connections in Diverse Vehicle Applications

News 2025-10-31

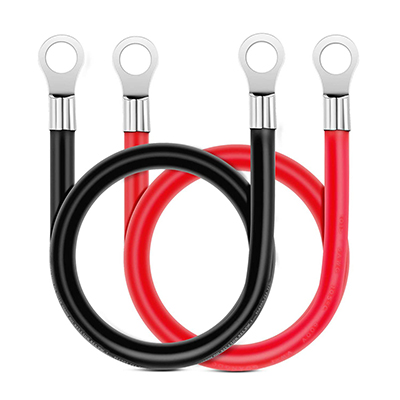

Wire harness parts play a crucial role in automotive systems, particularly in ensuring reliable electrical connections for components like the mass airflow sensor. These parts are essential for maintaining the integrity of signals that affect engine performance, fuel efficiency, and emissions control. In modern vehicles, high-quality wire harnesses help prevent issues such as signal interference or connection failures, which can lead to reduced vehicle reliability. By focusing on top-grade materials and precise engineering, manufacturers provide solutions that withstand harsh under-hood conditions, including temperature extremes and vibrations. This introduction highlights the importance of selecting superior wire harness parts to optimize automotive electrical systems and support overall vehicle functionality.

Key Applications in Automotive Systems

Wire harness parts are integral to various applications within automotive engineering, especially for mass airflow sensors that measure air intake for combustion processes. In engine management systems, these parts facilitate accurate data transmission, enabling precise fuel injection and ignition timing. They are also used in hybrid and electric vehicles where sensor accuracy is vital for battery management and energy efficiency. Additionally, in commercial fleets and high-performance cars, wire harnesses ensure durability in demanding scenarios, such as off-road driving or heavy-duty operations. By integrating seamlessly with other components, these parts enhance system reliability and contribute to safer, more efficient vehicle operations across different models and brands.

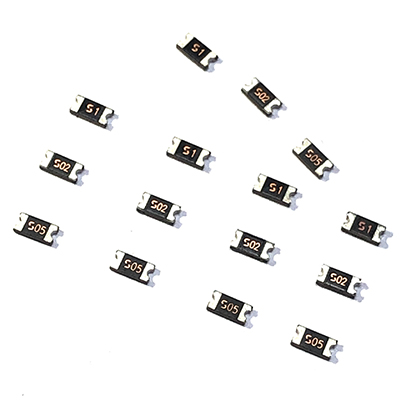

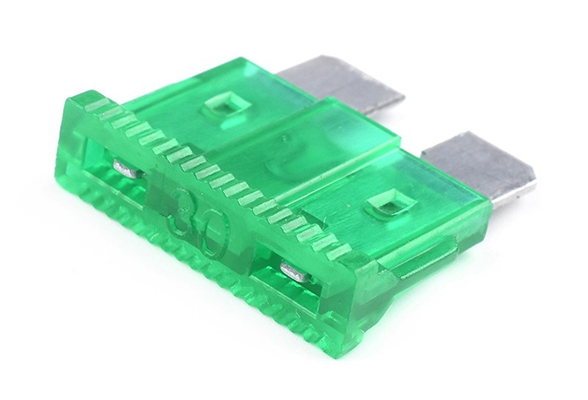

Performance Advantages and Material Benefits

Top-grade wire harness parts offer significant performance advantages, including enhanced conductivity and resistance to corrosion, which are critical for long-term reliability in mass airflow sensor connections. Constructed from high-quality materials like insulated copper wiring and robust connectors, they minimize electrical resistance and heat buildup, leading to improved sensor accuracy and reduced energy loss. These components also provide superior flexibility and vibration resistance, making them ideal for dynamic automotive environments. Furthermore, their design supports easier installation and maintenance, reducing downtime and costs for vehicle owners and technicians. Overall, investing in such parts ensures better system performance, longevity, and compliance with industry standards.

Frequently Asked Questions

1. What materials are commonly used in wire harness parts for automotive applications?

They are typically made from copper for conductivity, with insulation from materials like PVC or silicone to handle heat and moisture.

2. How do wire harness parts improve mass airflow sensor performance?

They provide secure, low-resistance connections that ensure accurate air flow readings, which are essential for optimal engine efficiency and reduced emissions.

3. What factors should be considered when selecting wire harness parts?

Key factors include compatibility with the vehicle’s make and model, quality of materials, and environmental resistance to ensure reliable performance over time.