Universal Automotive Fuses Enabling Cross-Platform Circuit Protection In Modern Vehicles

News 2025-11-17

Universal fuse compatible multiple car makes models electrical circuits are reshaping how designers and maintenance teams handle circuit protection across global vehicle platforms. By standardizing key parameters such as footprint, current rating, and interrupt capacity, these fuses simplify inventory, shorten repair time, and help ensure consistent safety performance in passenger cars, light trucks, and commercial fleets.

Key Electrical Performance Characteristics

Universal automotive fuses are engineered to meet strict automotive-grade standards, typically operating from 12 V up to 32 V systems used in conventional and mild-hybrid architectures. They are available in finely graded current ratings, often from 1 A to 40 A, enabling precise protection of low-power control circuits and high-load actuators. Accurate time–current curves allow stable operation under normal inrush conditions while opening rapidly during short circuits, reducing wiring harness damage and preventing thermal events. High-interrupt ratings help the fuse safely clear fault currents generated by powerful alternators and battery packs.

Mechanical Compatibility Across Multiple Makes And Models

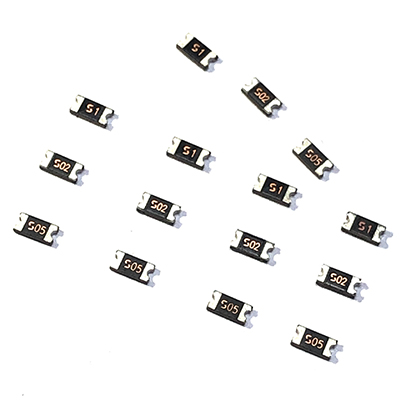

Compatibility across different brands is achieved through standardized blade dimensions, terminal thickness, and housing geometry. Universal blade fuses can be plugged into mini, low-profile, or standard fuse blocks found in European, American, and Asian vehicles, reducing the need for OEM-specific parts. The use of corrosion-resistant tin- or silver-plated terminals maintains low contact resistance in harsh environments, including high humidity and road-salt exposure. Color-coded housings and clearly printed ratings support quick identification during service, minimizing installation errors and downtime in workshops.

Application Scenarios In Modern Vehicle Electrical Systems

These universal fuses protect a wide range of circuits, including engine control units, infotainment modules, lighting systems, HVAC blowers, power windows, seat adjusters, and ADAS sensor supplies. In fleet vehicles, standardized fusing simplifies maintenance logistics, because technicians can stock one family of parts suitable for many models and years. Aftermarket upgrade shops use the same universal devices when adding auxiliary lighting, in-vehicle chargers, and communication equipment, ensuring that new loads are safely integrated into existing fuse panels without compromising OEM wiring integrity.

Performance Advantages For OEMs And Service Networks

From a manufacturing perspective, using a universal fuse platform reduces sourcing complexity and supports global vehicle platforms that share common electrical architectures. Consistent performance specifications enhance predictive design, allowing engineers to validate thermal behavior and fault-clearing margins across multiple product lines. For service networks, the performance stability of universal fuses results in fewer repeat failures, more accurate diagnostics, and improved customer confidence. High-temperature thermoplastic bodies and robust element design ensure long service life, even under continuous load at elevated ambient temperatures in engine compartments.

1. How do universal fuses improve maintenance efficiency?

Using one standardized fuse range means workshops handle fewer part numbers, leading to faster replacement, simplified stock management, and reduced risk of fitting the wrong rating.

2. Are universal fuses suitable for high-demand accessories?

Yes, as long as the selected fuse matches the current draw and voltage of the accessory, universal fuses can safely protect added loads such as amplifiers, auxiliary lights, and in-cabin power outlets.

3. Do these fuses support future vehicle platforms?

Universal automotive fuses aligned with current industry standards can be integrated into upcoming platforms that retain 12 V or 24 V architectures, offering a stable, long-term protection solution.