Temperature-Sensitive Design Thermal Fuse Enables Rapid and Accurate Circuit Protection

News 2025-11-27

Thermal fuses designed around precise temperature-sensitive principles play a central role in modern safety electronics. Unlike resettable protectors, these one-shot devices permanently open the circuit when a defined temperature threshold is exceeded, preventing overheating, smoke, or fire. Their fast response, compact size, and dependable cut-off behavior make them highly suitable for dense electronic assemblies where thermal runaway must be stopped in milliseconds.

Temperature-Sensitive Construction and Operation

A temperature-sensitive thermal fuse typically combines a fusible organic pellet, spring mechanism, and metal contacts sealed in a compact package. Under normal conditions, the pellet maintains firm contact pressure, keeping the circuit closed with very low resistance. When the surrounding temperature reaches the rated cut-off point, the pellet melts or decomposes, releasing the spring that instantly separates the contacts. This mechanical action produces a clean, irreversible open circuit. By selecting pellet materials and geometries carefully, manufacturers can offer narrow tolerance bands and sharp switching behavior, making the fuse highly predictable in demanding power electronics.

Key Performance Advantages

The primary advantage of a temperature-sensitive thermal fuse is its rapid activation exactly at the designed temperature range. The internal structure minimizes thermal inertia, enabling quick reaction to abnormal heat before components reach destructive levels. Low contact resistance supports high current ratings relative to package size, improving efficiency and reducing self-heating during normal operation. UL and IEC certifications, robust dielectric strength, and stable long‑term characteristics under vibration and humidity create a strong foundation for use in safety‑critical equipment. Engineering teams can select versions tailored to AC or DC loads, different insulation systems, and multiple mounting options.

Typical Application Scenarios

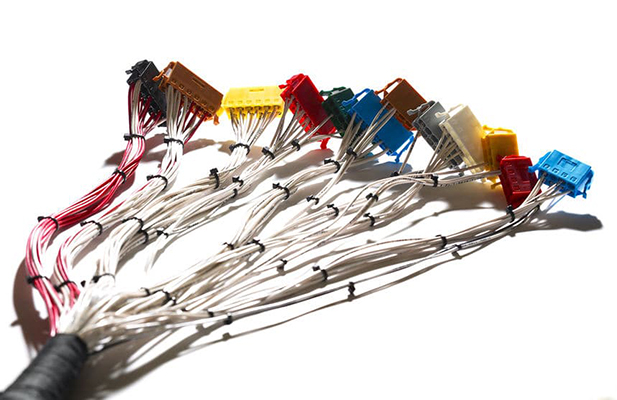

These thermal fuses are frequently integrated into household and industrial equipment that demands predictable overtemperature protection. In switching power supplies and chargers, they prevent damage caused by blocked airflow, component failure, or overload conditions. In battery packs, LED drivers, coffee makers, irons, HVAC controls, and smart meters, they act as the final safety layer if electronic control loops malfunction. Motor windings in pumps, fans, and compressors often embed thermal fuses directly into the stator, ensuring permanent disconnection when excessive heat arises due to locked rotor or overload. Their small footprint allows placement close to the most thermally stressed components for accurate temperature tracking.

Design-In Considerations and Selection

Successful application begins with choosing the correct cut-off temperature, which must sit above the maximum normal operating temperature yet below the level that could damage insulation, plastics, or nearby circuitry. Engineers must also verify rated current, operating voltage, and fault conditions such as short circuits or stalled motors. Proper thermal coupling to the heat source is essential; fuses can be clamped, potted, or taped to devices such as transformers, MOSFET heat sinks, or resistor networks. Designers should evaluate endurance under normal thermal cycling, expected life, and applicable standards in target markets. Early coordination between mechanical and electrical teams helps ensure safe spacing, insulation, and service accessibility in the final product layout.

FAQ on Temperature-Sensitive Thermal Fuses

11. How does a thermal fuse differ from a thermal switch?

A thermal fuse opens once at a defined temperature and then remains permanently open, requiring replacement. A thermal switch or thermostat opens and closes repeatedly as temperature fluctuates, providing resettable protection.

22. Where should the thermal fuse be installed in the circuit?

It is typically placed in series with the load or power input, as close as possible to the primary heat source so the body of the fuse accurately reflects the highest local temperature under fault conditions.

33. What key parameters should engineers check when selecting a thermal fuse?

Important parameters include rated cut-off temperature, operating current, maximum voltage, insulation class, agency approvals, and the thermal profile of the target application during both normal operation and worst-case failure modes.